JobPack® has been specializing in digital solutions since 1992, so we understand the importance of connecting the right data with the right people to make informed decisions.

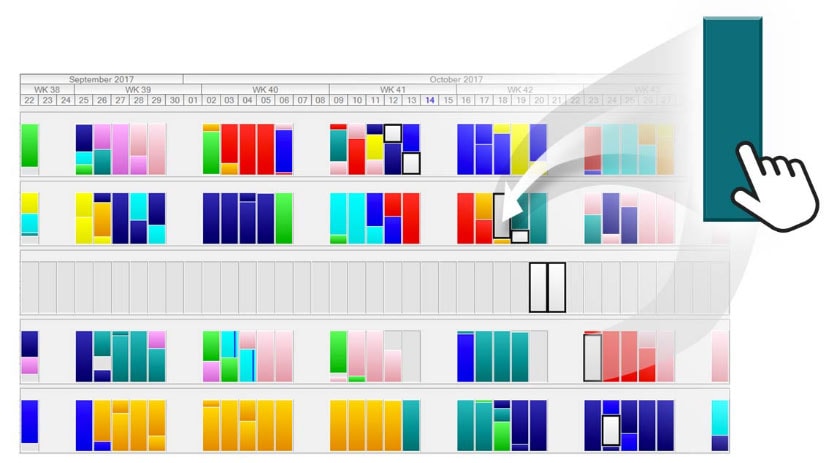

Welcome to what-if scheduling.

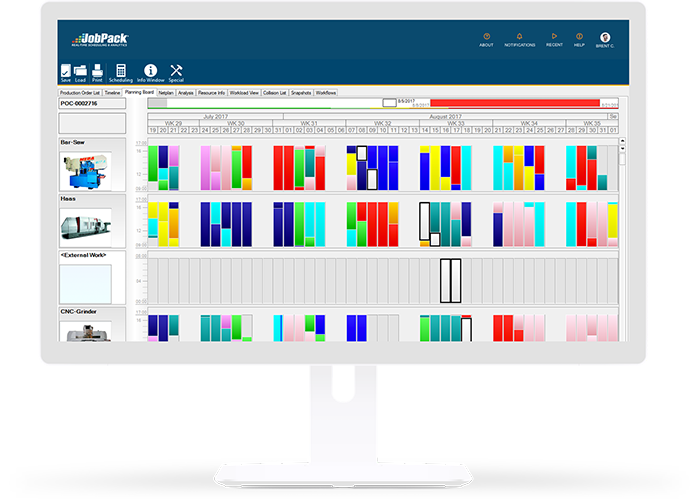

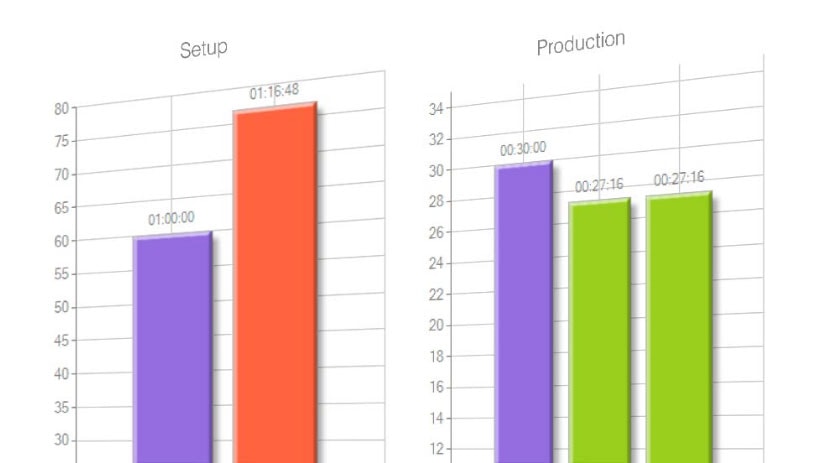

The Planning Board view lets you to see the impacts of production schedule adjustments without actually affecting the real-time operations of your shop. Try out a number of potential schedules until you find the perfect one that optimizes your workflow. Test the scheduling impact of accepting a rush order to determine whether you will need to plan for overtime.