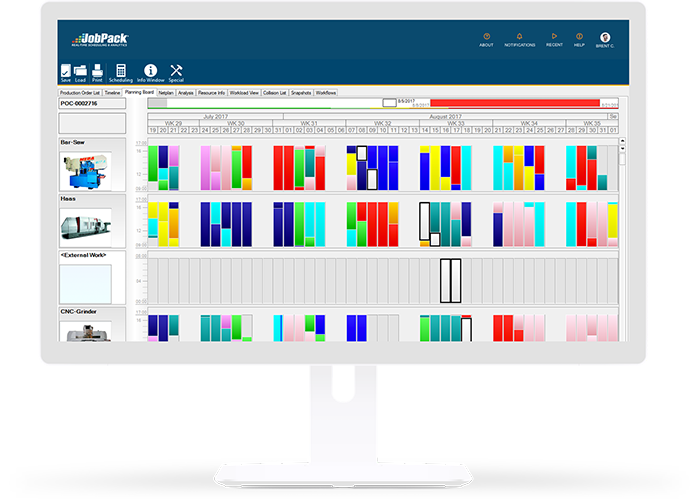

Goodbye spreadsheets: Introducing manufacturing software that will have you raising you on-time delivery rates along with your bottom line.

Across the country, manufacturers large and small are facing a common problem: operations on their shop floor don’t align with the tight production schedules they created on paper. There are simply too many unknowns to account for, and without real-time feedback on job status, few businesses can hope to accurately gauge their capacity—or meet critical delivery dates.

JobPack resolves these challenges by tackling the root cause: lack of data. With planning tools that account for every variable and up-to-the-minute machine monitoring, manufacturers can create schedules that match their operations, forecast capacity, and improve their overall efficiency.