Using Manufacturing Data Analytics to Calculate Overall Equipment Effectiveness (OEE)

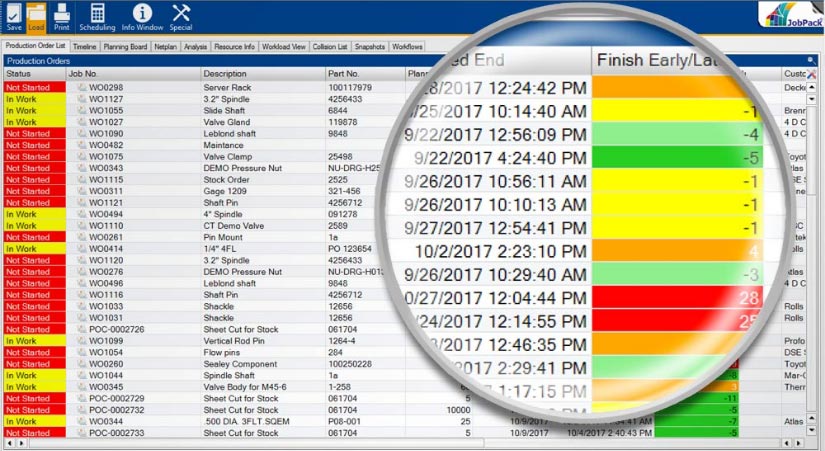

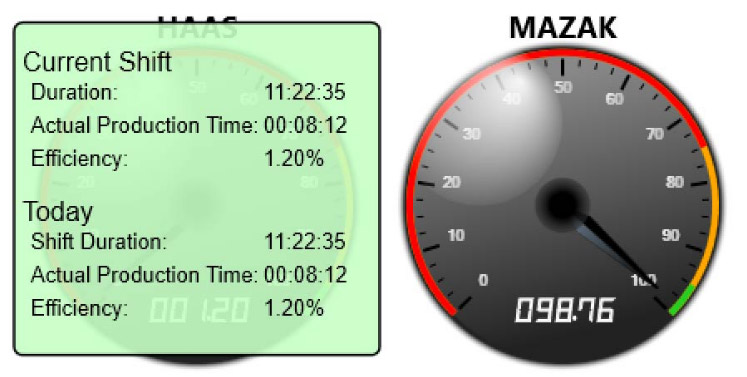

Understanding the performance of the machines on your shop floor is about more than knowing their overall run-time. If you expect a machine to be operational for six hours with two hours of downtime between jobs, but the machine actually runs for longer than that or requires additional maintenance between jobs, then you aren’t working with an accurate picture of its performance. Similarly, if it isn’t completing all of its booked parts within schedule parameters, or if too many of those parts are nonconforming, then you could be getting far less from your equipment than you realize.

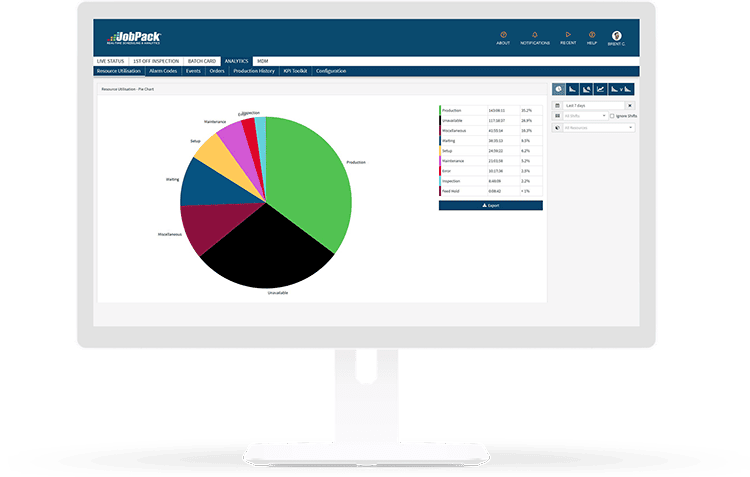

JobPack’s machine monitoring software, combined with data analytics gathered from the scheduler, allows manufacturers to fill in unknown variables. Work from a more complete picture to reduce waste, improve performance, and boost quality.