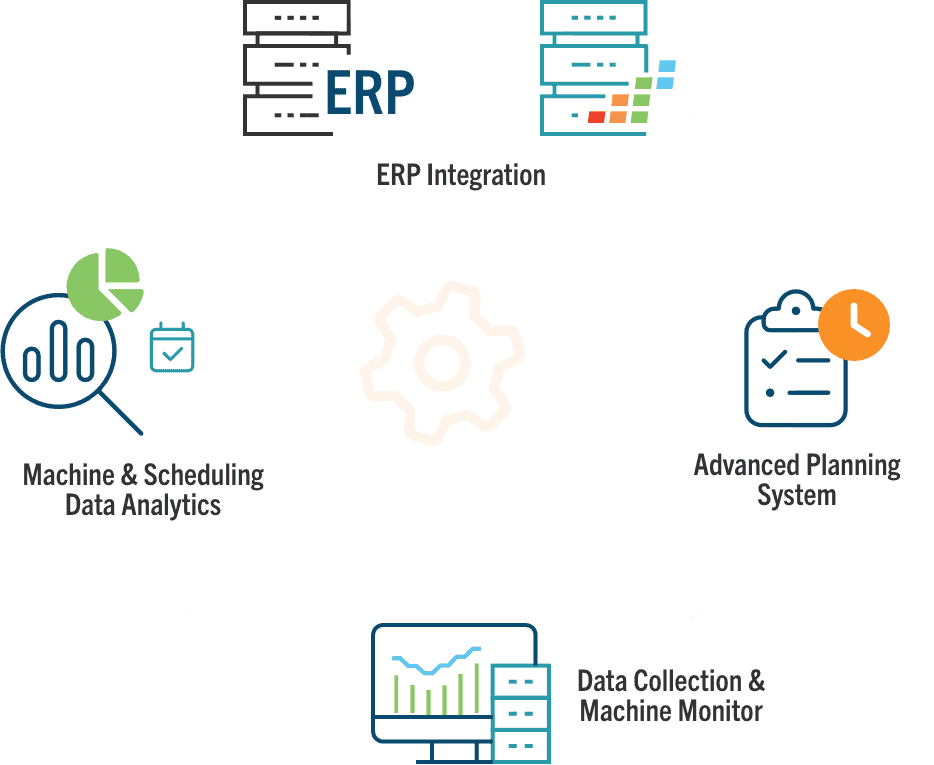

Interconnected Shop Floor

JobPack’s digital work queues improve communication between managers and machine operators, ensuring seamless transitions between scheduled production runs and a complete record of work orders. Owners can see which machines are running from the back office, allowing them to make informed decisions that support on-time delivery.

Greater shop floor transparency supports high level decision making while empowering schedulers and operators to identify and act on areas of improvement.

- Optimize the production schedule to reduce the time that machines are standing idle during working hours.

- Digital batch cards keep crucial production information in one place while eliminating paper packets as a source of confusion.

- WIP tracking lets users input rich data at every point in production, providing management with a detailed account of job progress.

Drag and drop production scheduling combined with “what if” scenario planning keep everyone on the same page.