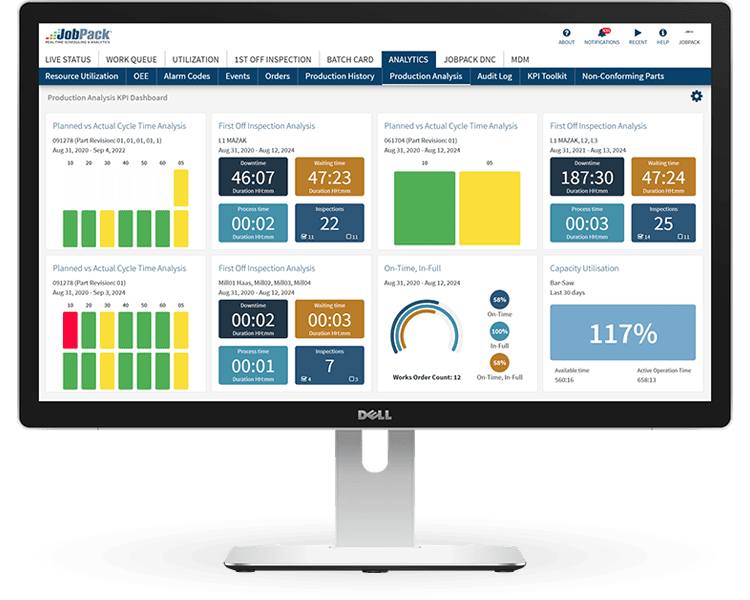

Overall Equipment Effectiveness (OEE)

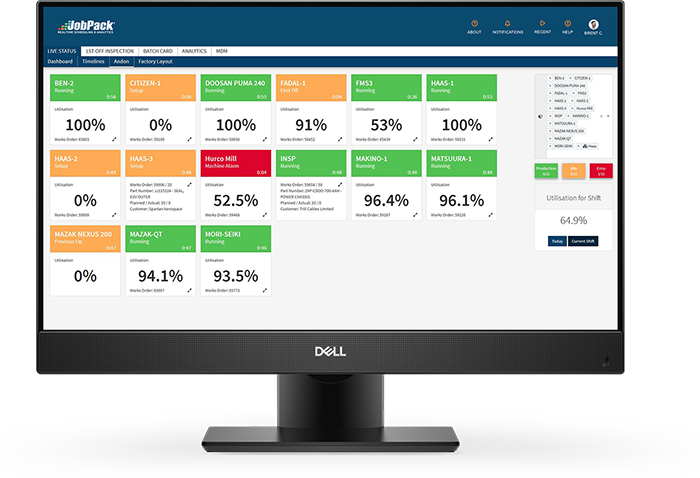

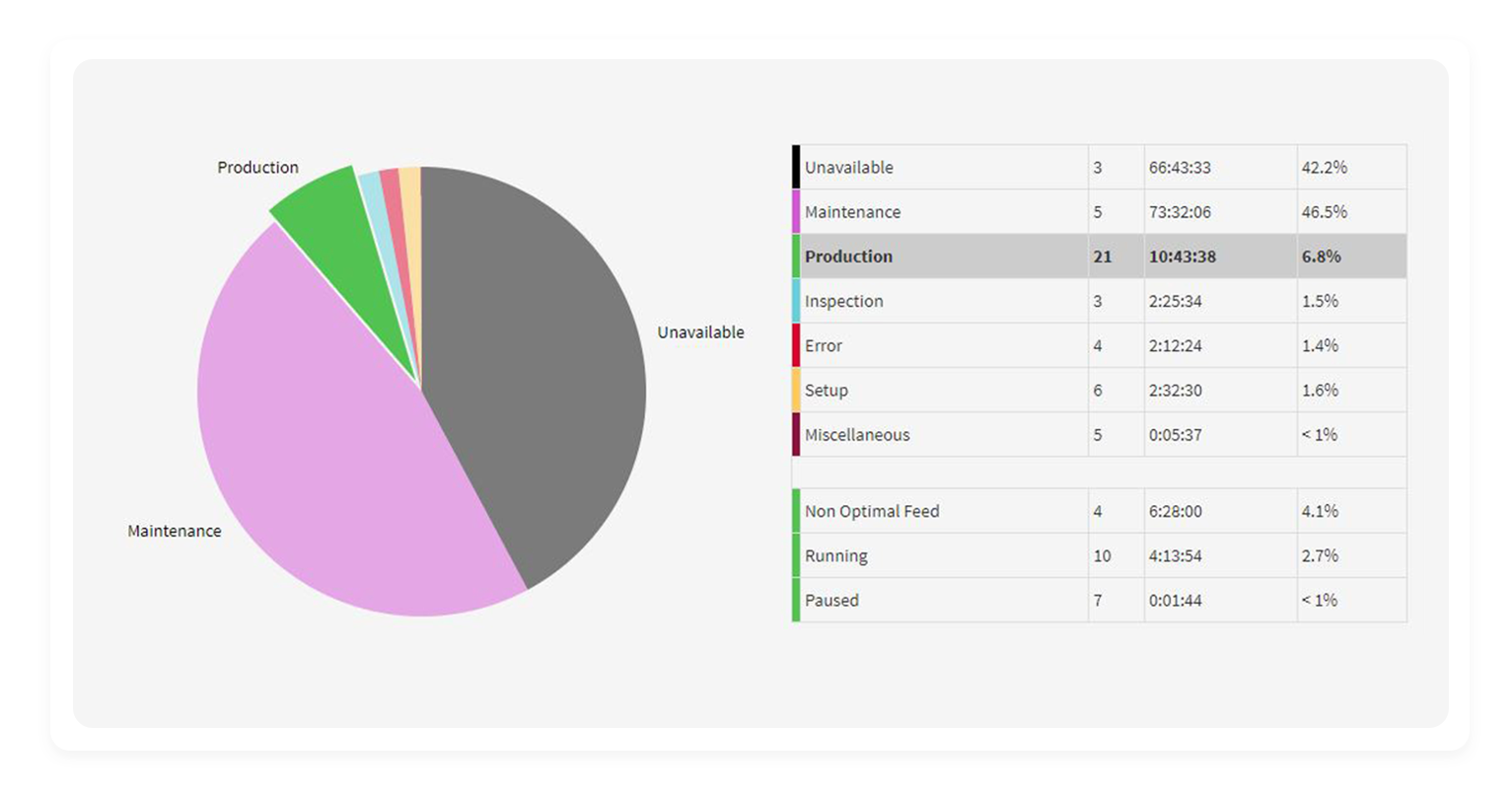

When it comes to improving machine performance, manufacturers typically begin with utilization, which is the percentage of time a machine is running. No machine is running 100% of the time, due to setup time between parts, regular maintenance, and other variables. A machine that is fully booked and only not running during expected downtime would have achieved optimal equipment effectiveness. But the manufacturing floor is never that simple.

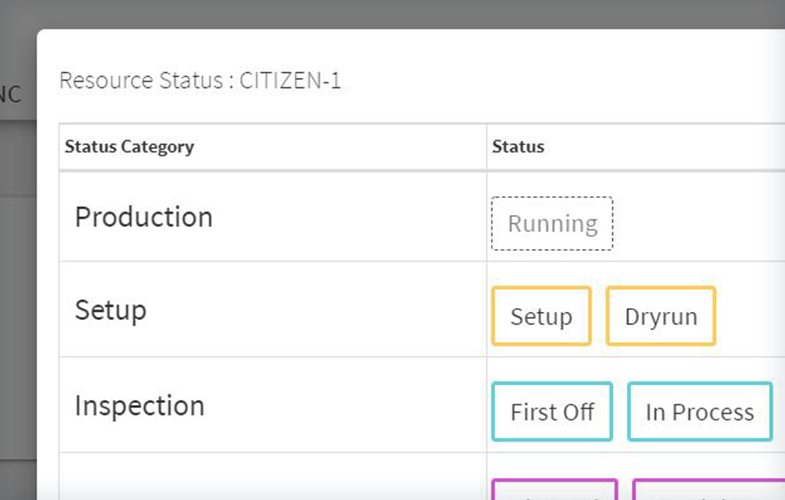

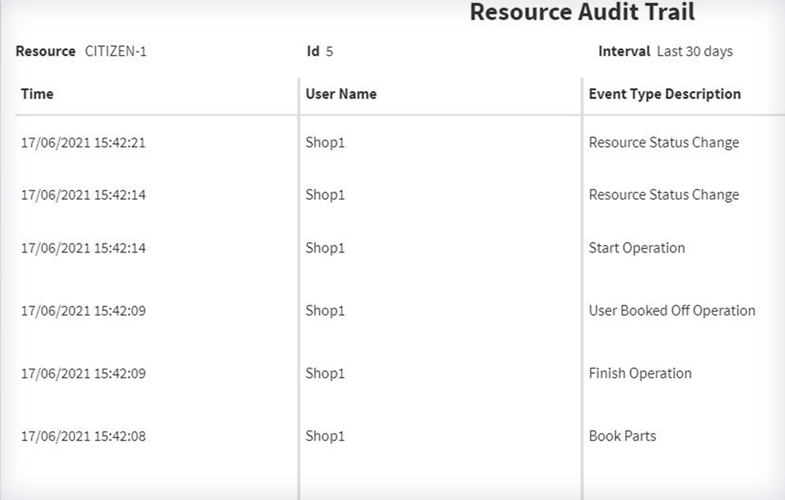

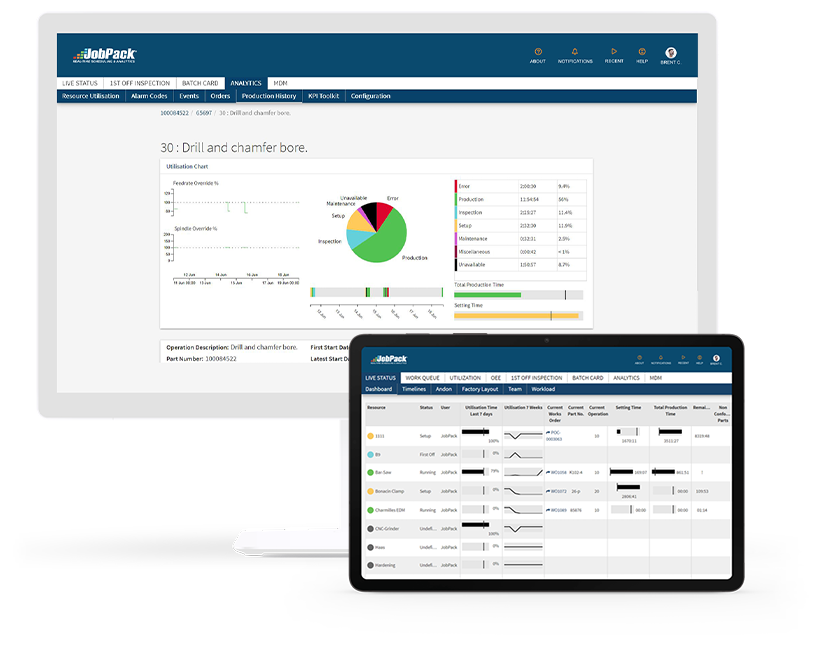

Machine monitoring helps manufacturers refine their OEE calculations by identifying planned vs. unplanned downtime, pinpointing areas where production time ran longer than expected, and highlighting problem areas that incur rework costs.