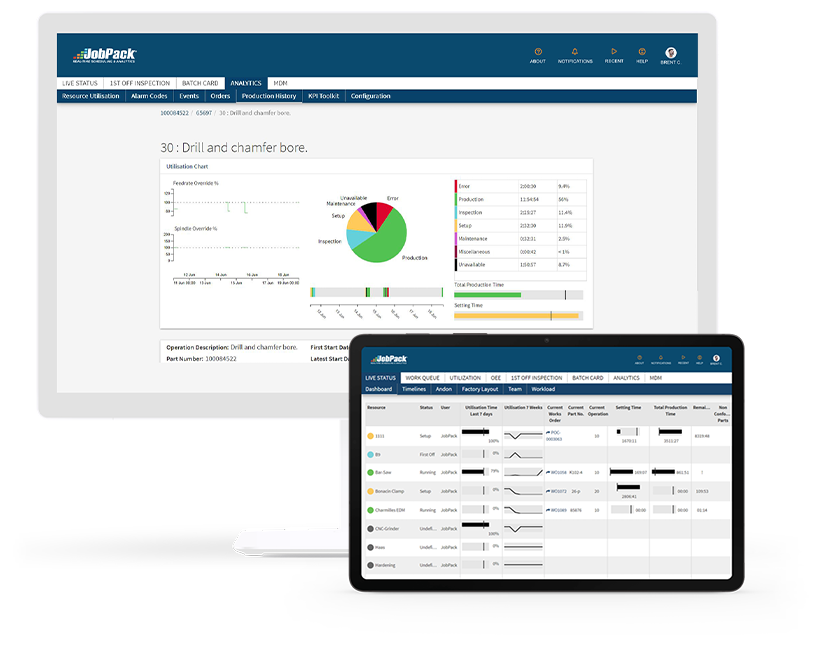

CNC Machine Performance Analysis

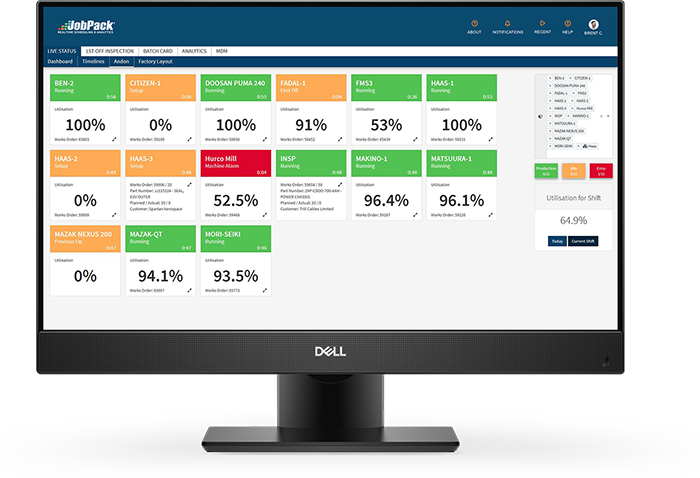

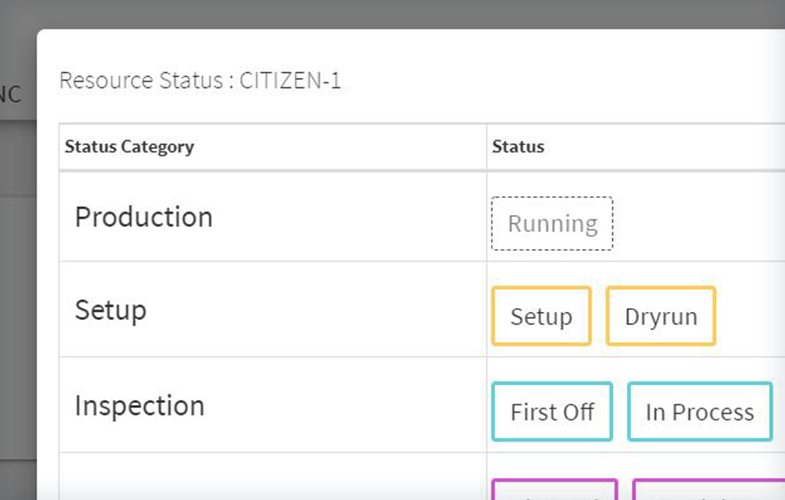

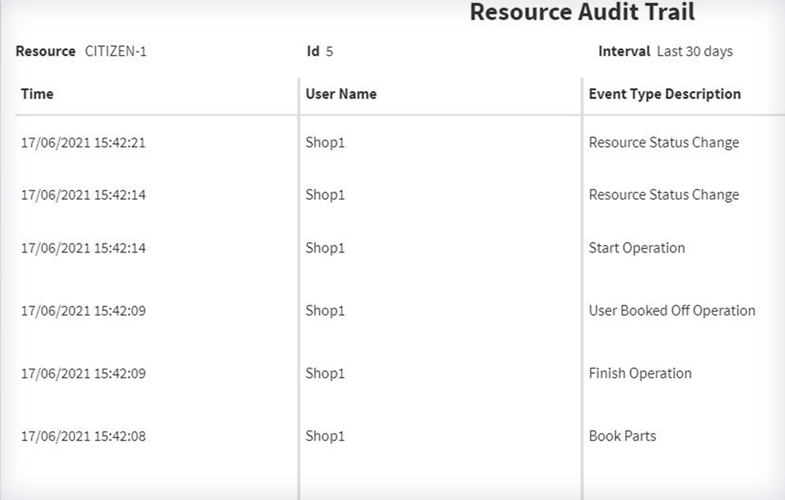

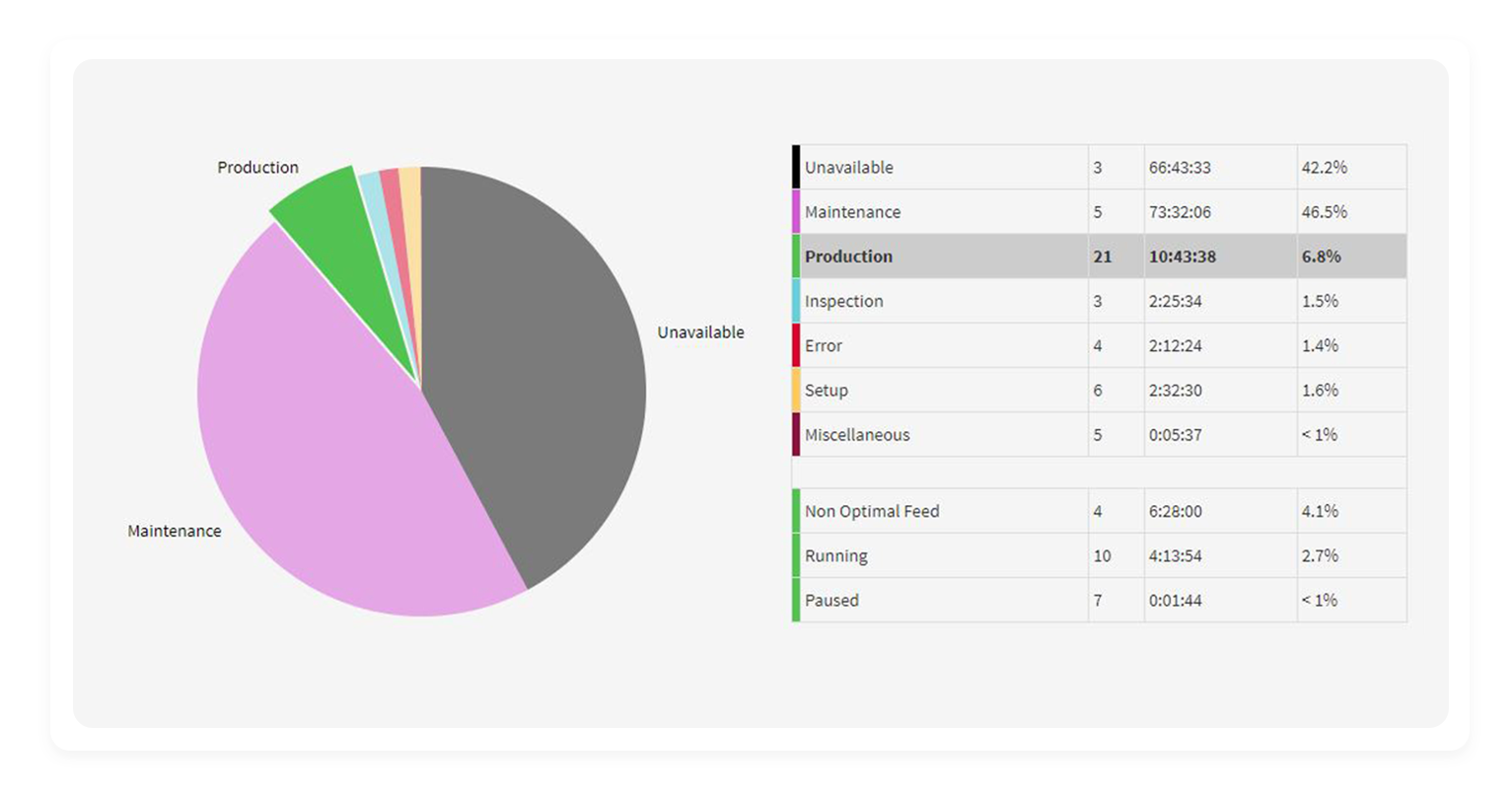

The last thing you want to be doing is guessing or using imprecise methods to track the productivity of your machines. JobPack® provides real-time, deep-dive reporting to help make informed adjustments and execute plans based on real metrics day-to-day, year-over-year:

- Reduce waste, downtime and cycle times

- Increase capacity on all assets

- Improve quality

- Boost on-time delivery

- Use your own ERP data like it is supposed to be used

- Enhance reporting of KPIs, utilization, and performance