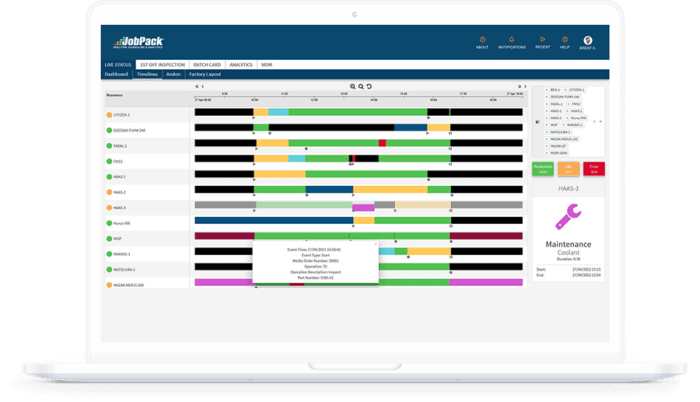

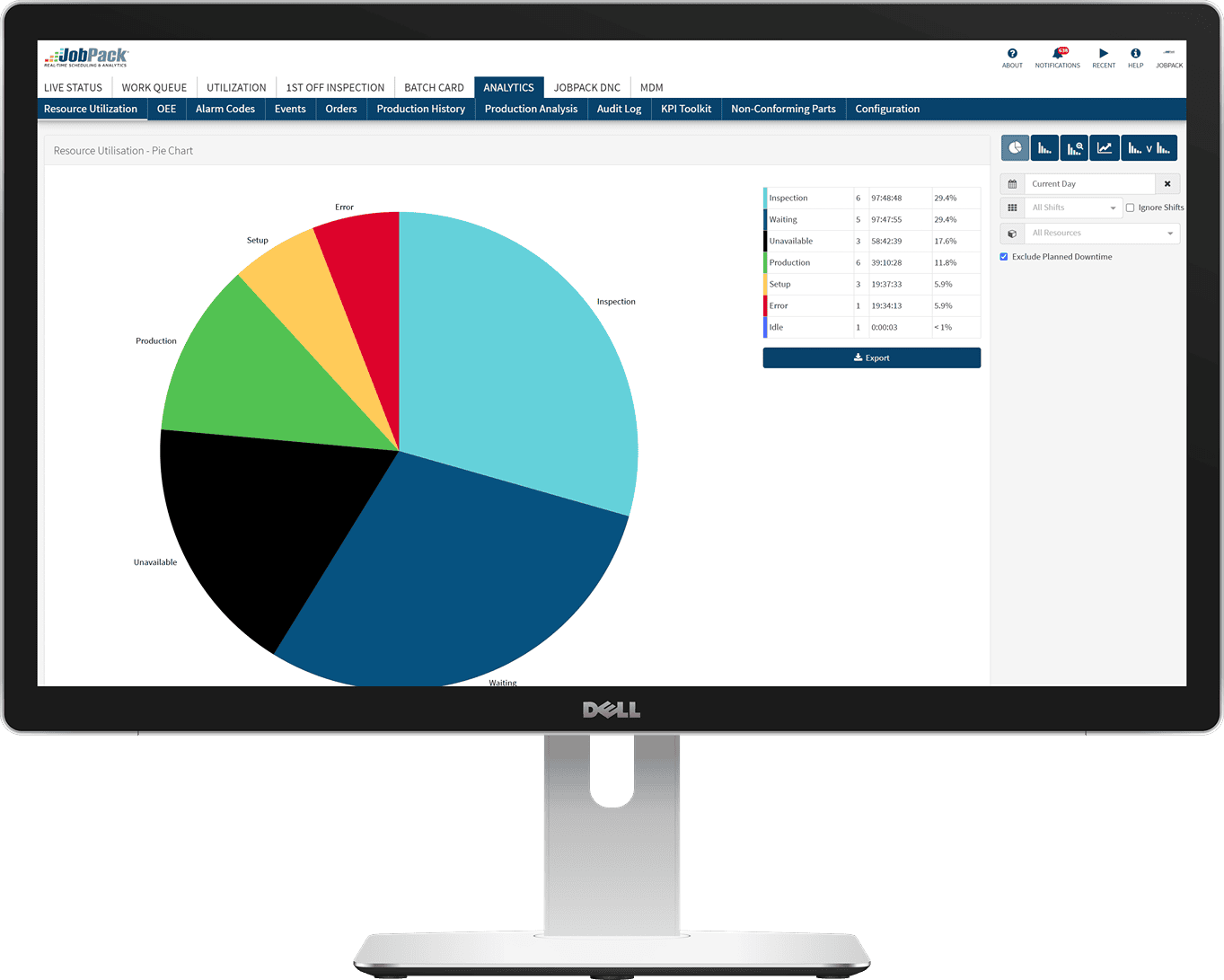

Being connected to every machine gives you a deeper understanding and real-time visibility of how the entire shop floor is performing, enabling you to decrease machine downtime, reduce errors, minimize waste, and increase productivity.

Solutions / Shop Floor Data Collection

Accurate, consistent production data to improve your on-time delivery performance.

Take the guesswork out of your day-to-day operations.

JobPack’s Shop Floor Data Collection WIP Booking Solution has been specifically designed with shop floor users in mind. The interface is uncluttered, easy to navigate and simple to learn, enabling operators to complete their daily work activities with ease. We make it straightforward for users to enter accurate, consistent production data that is of real benefit to your manufacturing business and improving your on-time delivery performance.

Need support pitching JobPack® to management?

We’ve got you covered.

Digital work queues support on-time delivery.

The digital work queue for each resource is driven by work orders released from the JobPack Scheduler or your existing ERP system. Each operation on the queue contains the critical targets, including planned batch setup and part production times; operation start and finish times and the work order due date.

Access to this data supports informed decision making and the ability to make a direct contribution to on-time delivery performance.

- Prevent operations from being started out of sequence.

- Prevents the completion of an operation that has a first off inspection outstanding.

- Allows multiple jobs to be started in a resource.

- Delivers shared work queues for grouped resources.

- Generate work queues for grouped resources.

- All activities and user entries for resources, work orders, and operations are captured and digitally stored.

- Users can attach external files to operations, making them part of the batch record.

- Users can add comments and view notifications.

Digital batch cards enable paperless production.

Eliminate clutter from your shop floor with digital batch cards that keep crucial production information in place while maintaining a complete audit trail. Digitized batch cards remove a common source of manufacturing error by making it easier to update and track work orders without creating new paperwork with every change.

Digital batch card data keeps managers and floor workers on the same page while automating the production record.

- Full works order audit trail.

- Operations stamped upon completion with the username, date and time.

- Users can quickly identify completed operations and take action to shorten production time.

- Complete batch cards become a complete, detailed historical record.

Work-in-progress (WIP) tracking delivers shop floor insight.

The operator can confirm the start and completion of each operation that is scheduled for work-in-progress tracking. User input creates a rich picture of what is actually happening at each station, enabling clear communication across all levels of the business, making it easier to identify the source of problems without assigning blame.

With WIP tracking, operator feedback from the shop floor provides management with a detailed account of job progress.

- The quantity of machine parts produced can be entered manually or automatically, and can be updated progressively during the batch, at the end of the shift or upon completion.

- Users can enter reasons for non-conformance to help identify improvement opportunities for eliminating errors and reducing waste.

- Users can add comments and view notifications.

- Depending on your system configuration, the Work-In-Progress Tracking will also update the operation status in your scheduling system and can also be transferred to your ERP system.

Plant & Operations Managers

Improve Shop Floor Throughput.

Designed for the Manufacturing Floor

- Improve operational efficiency by understanding performance down to the individual operation.

- Reduce administration time and costs.

- Simplified and streamlined data capture process to reduce data entry errors.

- Improve visibility of work order status and material traceability.

- Improve communication, shared information and increased visibility to drive on-time delivery performance.

- Achieve greater data accuracy and on-time deliveries.

- Optimize work order performance by improving output and reducing scrap levels.

- Capture the time attributed to work orders supporting more accurate job costing.

- Provides reliable data for continuous improvement strategies.

- Close integration with our other modules provides a seamless user experience-supporting the multi-tasking, multi-functional and time pressured demands of the modern manufacturing environment.

Order Progress Tracking

View a week-by-week visual summary of the progress of each work order. The graphical progress bar indicates the status of each operation and whether full part quantities have been scheduled. It enables users to quickly identify orders that are planned or due to be completed late.

KPI Reports

KPI reports enable you to drill into a detailed historical analysis of the progress and times of operations for individual work orders, including a comparison of planned versus actual job times and costs.

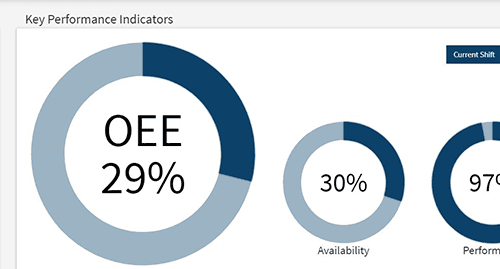

Overall Equipment Effectiveness (OEE)

Calculate actual equipment effectiveness more accurately with data that shows planned hours vs. available hours vs. runtime hours, planned parts vs. booked parts, and good parts vs. nonconforming parts.

Real-time feedback from shop floor data collection supports the bottom line.

Every schedule is an estimate based on past performance and runtime expectations. Without real data about actual operation run times, those estimates are based on the scheduler’s best guess and gut instinct. By collecting data directly from the machines themselves, manufactures can create more accurate schedules that account for every variable. The business benefits can be felt on the bottom line: more projects delivered on time, better capacity prediction, reduced downtime, and fewer hours lost to the overtime scramble.

Software Comparison Guide: Get to Know Your Options

JobPack® has been specializing in digital solutions since 1992, so we understand the importance of connecting the right data with the right people to make informed decisions.