All levels of your organization will benefit from the highly adaptable, efficiency boosting scheduling and analytics of JobPack®. Our visually intuitive production scheduling solution will unleash the potential of your business.

Why JobPack®

Production planning that eliminates blind spots, boosts efficiency, and tracks every variable.

Tame the chaos of your shop floor with data-driven scheduling and machine monitoring software.

Manufacturers are plagued by stubborn shop floor problems such as projects running past their delivery date, crews pulling overtime to keep up with the workload, and managers unable to plan effectively due to a lack of accurate information. Our Manufacturing Execution System (MES) promises clarity.

Need support pitching JobPack® to management?

We’ve got you covered.

Why JobPack® Works

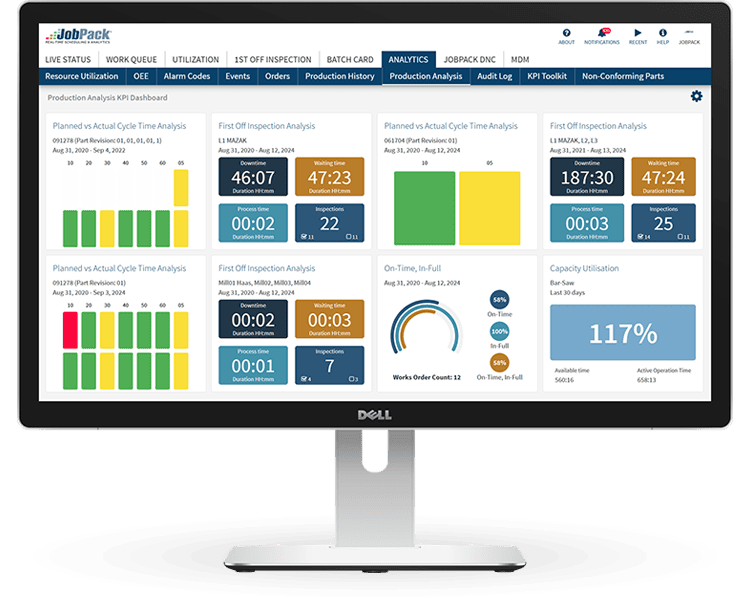

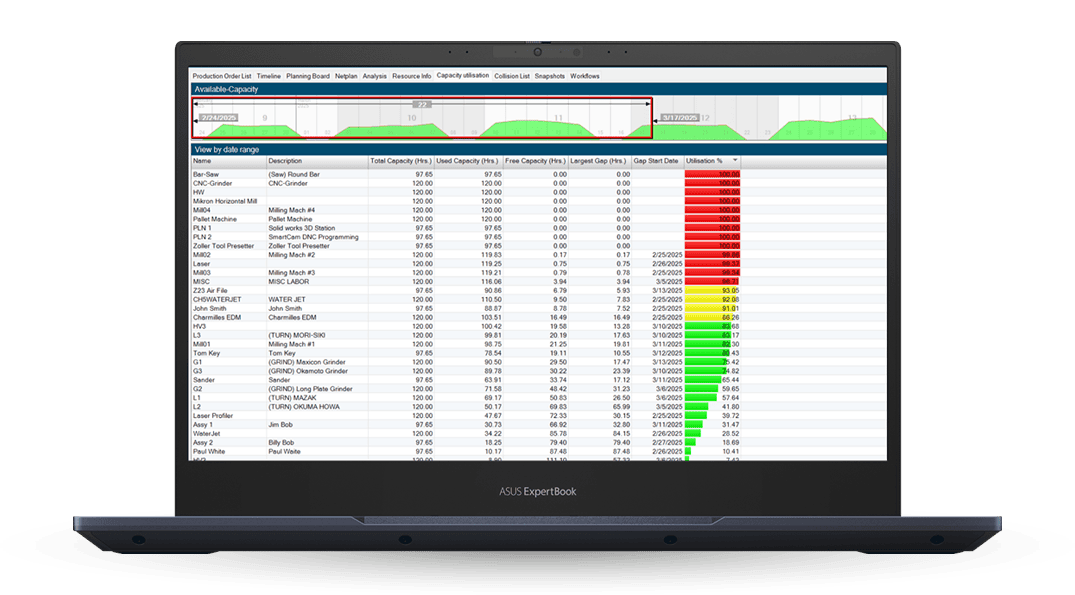

- Color-coded interfaces allow users to easily identify project status.

- Drag-and-drop scheduling makes it easy to adjust jobs.

- Analytics dashboard eliminates knowledge gaps and improves planning.

- Pinpoint problem areas and measure process improvements.

- What-if scenario planning that prevents disruption from unknown variables.

- Visualize everything in one place to prevent production clashes.

- Integration with ERP and MRP systems for full -operational overview.

- Customization to work with specific business requirements.

- Ability to operate as a stand-alone production scheduler.

- More informed decision-making for owners and the C-suite.

- Improved communication between managers and the shop floor.

- Real-time data for purchasing and inventory management.

30+ Years Solving Manufacturing’s Hardest Problem

JobPack was founded in 1992 with one clear mission: give manufacturers a better way to plan, schedule, and execute production — without the complexity or cost of enterprise systems designed for companies three times their size.

What started as a focused solution for discrete manufacturers has grown, over three decades, into a platform trusted by more than 1,100 industrial companies across North America and Europe. That’s 1,100+ plant managers, operations teams, and shop floor supervisors who chose JobPack, got up and running in weeks — not months — and never looked back.

We’ve grown through recessions, technology shifts, and the rise of Industry 4.0 — not by chasing trends, but by staying relentlessly focused on what manufacturers actually need: shipping on time, staying on budget, and keeping machines running at full capacity.

Headquartered in Elgin, Illinois, JobPack remains privately owned and deeply committed to the manufacturers we serve. We’re not a venture-backed startup with a roadmap built in a boardroom. We’re a company that grew up on the shop floor — and after 30+ years and over a thousand successful implementations, it shows in everything we build.

JobPack's credibility isn't built on marketing campaigns — it's earned through performance. Over 30+ years of continuous operation, JobPack has built a track record that speaks for itself across the manufacturing software industry.

Request a Demo

Intel Innovation Recognition

European Distribution Partner

Seiki Strategic Partnership

8.62/10 overall rating

4.1/5 overall rating

Community Validated Choice

YOUR ERP ISN’T AN MES.

Have you invested in an ERP with a built-in production scheduler only to be disappointed in its capabilities and lack of operational insight? Many of our clients came to us experiencing this pain point—and we’re more than happy to relieve it. Your ERP is an essential planning tool for your business, but ERP developers often treat production scheduling as an afterthought, leaving manufacturers struggling with an underpowered planning tool.

As an MES, we’re purpose-built to keep your shop floor running. We’re not here to compete with your ERP—we’re here to integrate with it, and ensure that you have the best software tools to run your manufacturing business at every point of your operation.

Proven by 1,100+ Manufacturers. Live in 6 Weeks.

Up and Running in 6 Weeks

ERP-Agnostic by Design

Visual Scheduling

Modular

JobPack gives us better accuracy on delivery promises. But even more important is that when there are problems, we see them weeks before projects are due, so we have time to take action.

Our Team Has Been in Your Shoes

Victoria Gurney

Industry Author & Content Lead 25 years in manufacturing and at JobPack. Victoria ensures everything we produce reflects the real-world challenges manufacturers face every day — not just what looks good on a spec sheet.

David Welsh

President Under David’s leadership, JobPack has grown to 1,100+ global installations and evolved from a production scheduling tool into a full Industry 4.0 solutions platform — without ever losing the practical, cost-effective approach manufacturers depend on.

Implementation & Integration Specialists

Our implementation team combines IT and shop floor expertise. Many trainers were former JobPack users, so they teach from real experience. Our engineers support over 20 ERP systems and consistently deliver successful integrations.

Software Comparison Guide: Get to Know Your Options

JobPack® has been specializing in digital solutions since 1992, so we understand the importance of connecting the right data with the right people to make informed decisions.