JobPack® has been specializing in digital solutions since 1992, so we understand the importance of connecting the right data with the right people to make informed decisions.

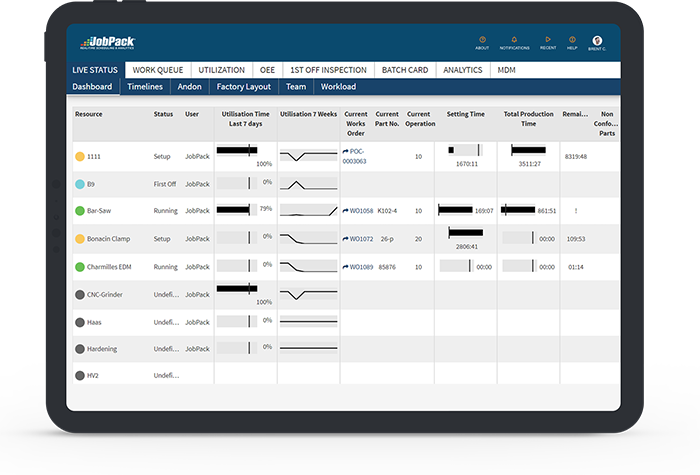

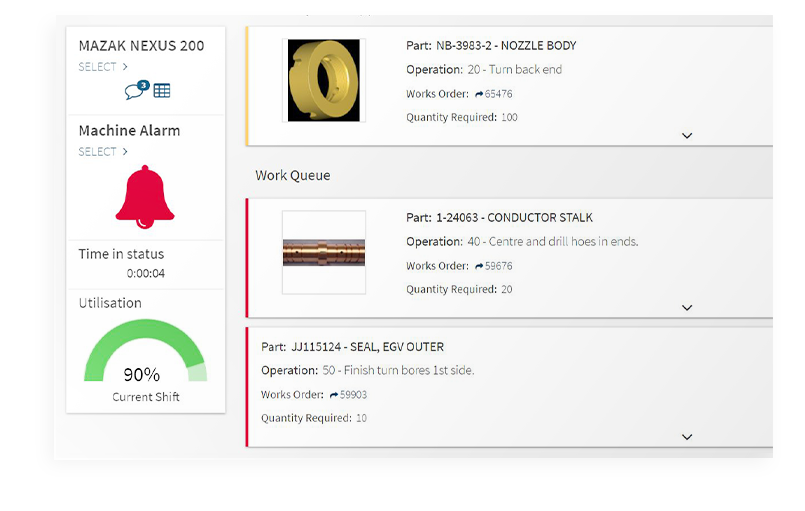

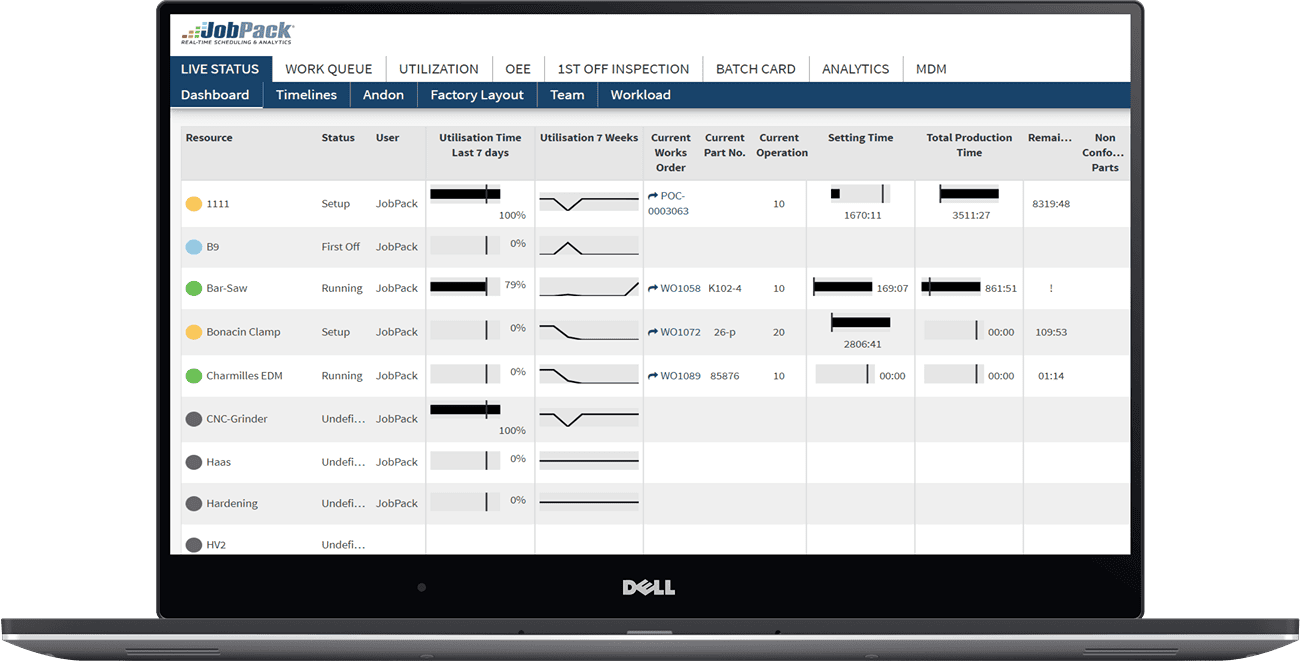

Machine monitoring analytics bring insight to the workings of your shop floor.

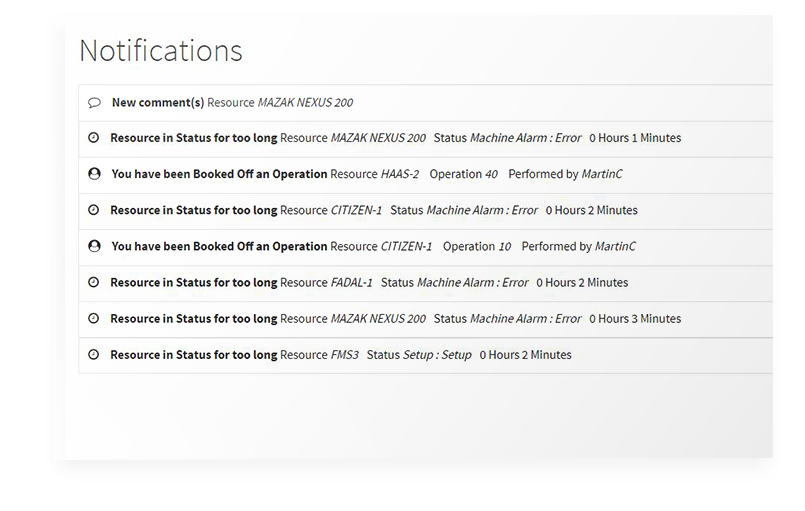

Uncovering the root cause of inefficiencies begins with better data. JobPack’s machine monitoring module helps you gather machine performance data and compare reports to identify bottlenecks and optimize utilization. Compare planned time vs. actual time to see where the slowdown begins. Combine this with data about your booked parts vs. nonconforming parts to better calculate OEE.