JobPack’s near-term wins evolve into downstream transformations for your shop.

One of JobPack’s core advantages is that implementations can move quickly, with the first benefits felt in as little as weeks. And for many organizations, reliable scheduling and real-time transparency are game changers in their own right. As every production scheduler knows, however, changing one variable can have a raft of downstream effects. In JobPack’s case, the data collection and transparency that make production scheduling work can also sow the seeds of significant benefits for the shop ecosystem as a whole.

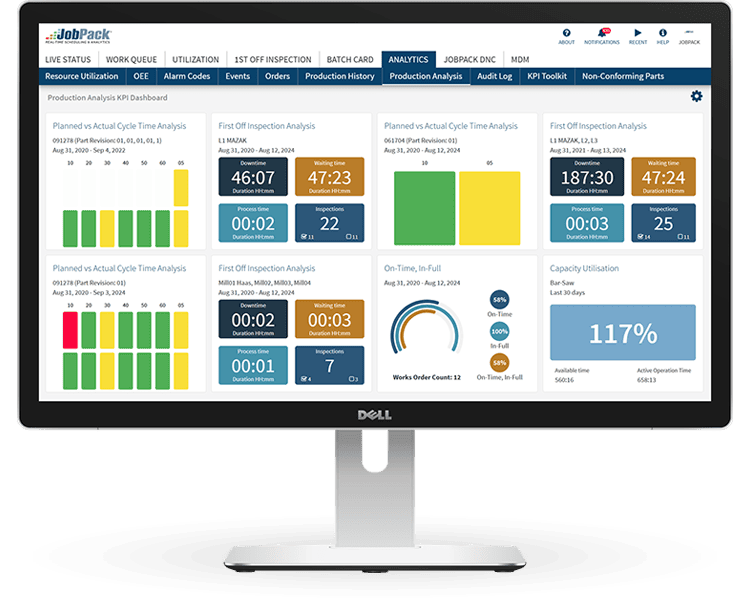

JobPack’s rich data collection and analytical tools capture the information that already exists in your shop and put it to work for you in new ways. As a result, you can uncover trends and insights in your production process that lay the groundwork for a next-generation approach to manufacturing. Here’s how JobPack helps you find new efficiencies, attract new opportunities, and grow your business.

Visibility means optimization.

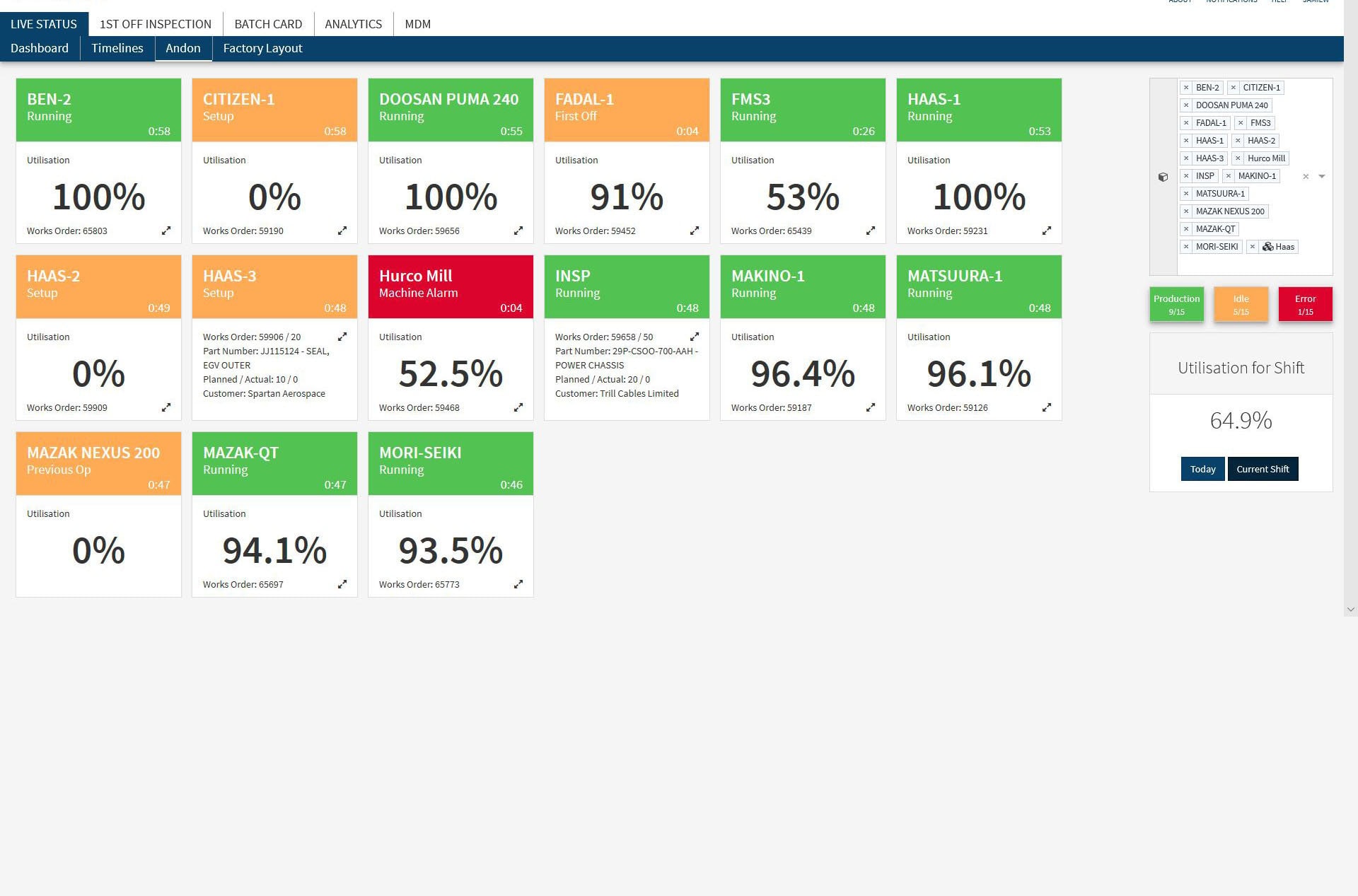

It’s tough to manage what you can’t see. With so many moving parts on the shop floor, it’s hard enough just to get a complete picture of your production process, much less analyze it for opportunities to improve. JobPack provides a platform for full visibility into your production process, letting you track performance, see real-time status updates, and run analytics to identify trends.

Visibility tools:

- Machine monitoring

- WIP tracking

- Data analytics

With these features, you can begin to pinpoint bottlenecks in your production line, like a machine that regularly sits idle while waiting for supplies. Armed with detailed information, you might choose to store supplies closer to the machine, cutting down on idle time and the need for operators to make warehouse trips. In the grand scheme of things, it’s a small change, but the efficiency gains add up over time into undeniable value.

Improved visibility opens the door for more and more of these marginal gains, leading to a more fully optimized shop. Streamlined workflows mean greater productivity, lower costs, fewer opportunities for error, and an improved experience for operators, boosting your shop’s performance as a whole.

An agile shop thrives on change.

Disruptions and changes are a guarantee in manufacturing. When they happen, shops need to be able to pivot quickly to avoid wasting time or resources—but without the right information, production processes are too unwieldy to change course at speed. Shops risk missed delivery dates, flawed product, or even just missing out on a job that could have filled a hole in the schedule.

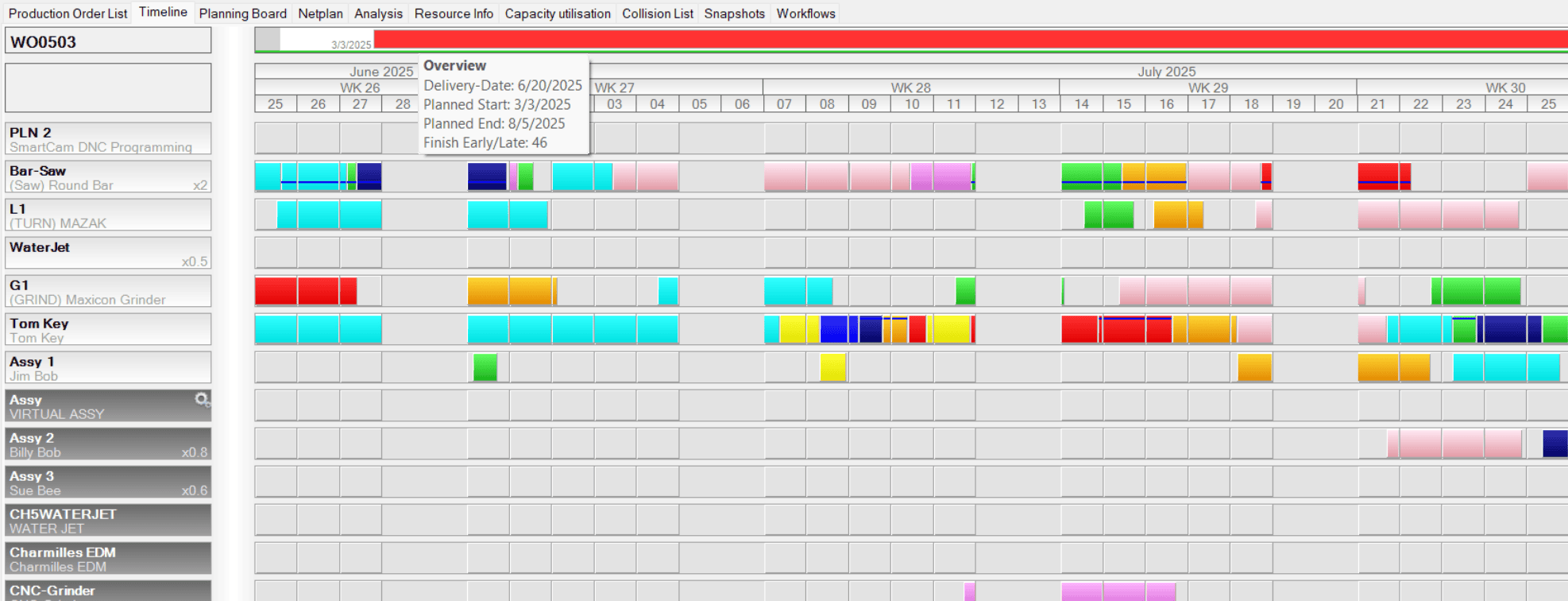

Agility tools:

- What-if planning

- WIP tracking

Up-to-the-minute monitoring grants you a complete, accurate picture of your shop’s current capacity. And with flexible planning, you have a low-stakes way to see how scheduling changes could affect it. Drag and drop jobs to check the impact on your other delivery dates and your machine utilization, and then revert the changes without affecting the production environment—or save the new schedule and shift focus. When your shop is equipped to adapt, change is an opportunity instead of a threat.

Paperless operations expand your horizons.

Documentation is crucial in manufacturing. It’s how you record the history and status of a job, how you communicate between operators and across shifts, how you audit work, and how you build institutional knowledge. But for many manufacturers, the paper trail is still recorded on actual paper.

In an increasingly fast-paced manufacturing sector, paper packets are a sharp limiter of growth. Paper costs money, takes up space, and gets lost. The information on it goes stale. It’s labor-intensive to search and examine. In short, if you’re reliant on paper, it’s impossible for your shop to scale up effectively. On top of that, there are contracts that you’ll simply be unable to land.

Audit tools:

- Machine monitoring

- WIP tracking

- DNC/paperless manufacturing

JobPack enables fully digital documentation that automatically captures job activity, assigns unique tracking identifiers, and centralizes job information at a single, accessible point of reference. This degree of transparency and traceability gives you the tools to bring your shop into compliance with government audit and security standards, making it easier to win government contracts and opening whole new revenue streams for your shop.

Root-cause analysis emphasizes results over fault.

When a job goes wrong, everyone in the shop is invested in finding the cause. Unfortunately, in the absence of concrete information, the process of finding out can raise tensions within the workforce. No one wants to feel like they’re being accused of falling down on the job, and frustration around errors or logistical hurdles can sometimes spiral into blame.

Root-cause analysis tools:

- Machine monitoring

- WIP tracking

- DNC/paperless manufacturing

Instead, detailed monitoring tools put answers at your fingertips. Trace delays and errors to their source, eliminating much of the uncertainty that can inspire hesitation or hard feelings. Moreover, when you can confidently point to a root cause, you can focus your energies more efficiently and steer your shop toward solutions.

Better predictions breed confidence.

Everyone knows the experience of a flawed estimate coming back to bite them. As a manufacturer, you estimate the turnaround time on jobs constantly. Often, it’s the first impression that you make with a new potential customer. Estimates are how you schedule work and manage day-to-day operations. Naturally, you’d want them to be as accurate as you can make them—but your estimates are only as good as your information, and standard lead times can let you down.

Predictive tools:

- What-if planning

- Machine monitoring

- Data analytics

Shop management is a whole lot easier when you can see the future. JobPack’s detailed data collection over time lets you build predictions that more closely reflect the reality of your individual shop: your capacity, your equipment, your suppliers, your staff. Incorporate real-world shop data and live monitoring to set precise expectations with customers—and then impress by delivering.

JobPack is your shop’s step up to the next level.

Wherever your shop is along the scale of digital transformation, JobPack is flexible and lightweight enough to slot in and begin delivering benefits. It can stand alone as an MES, or integrate with your existing ERP to add detailed production insights to your information arsenal. With JobPack in place, your shop can start to take advantage of the production data that’s been there all along—unlocking all-new opportunities for growth and transformation.

To see JobPack in action and explore the possibilities for your shop, contact our service representatives today.