How JobPack Empowers You to Scale Your Manufacturing Business

JobPack is a perfect starting point for digital transformation—and all the benefits that come with it.

The ability to expand your manufacturing shop, take on more jobs, and increase your throughput depends on a range of factors. Economics play a large part. So do the labor market, a certain amount of luck, and your own hard work. But much like manufacturing itself, good results also depend on having access to the right tools.

Scaling up production is a big and exciting step, but to ensure that it sticks and your investments pay off, staying organized is essential. If your shop’s processes can’t absorb the increase in work and logistical demands, your growth prospects are at risk of fizzling out.

Production scheduling is a core hurdle for any manufacturing shop, and it’s a responsibility that increases exponentially in scope as your business expands. That makes it an essential first challenge to solve for any shop trying to grow—but it doesn’t need to be an overwhelming one. A lightweight production planner like JobPack can transform the way you manage your shop floor, without losing momentum or energy to a years-long implementation process. Here’s how JobPack prepares you to level up your operations.

More jobs, more efficiently

Any production scheduler knows that one small schedule shift can have a hundred game-changing downstream impacts. Moving one job back by even a single shift can tie up an essential machine for an extra cycle, delaying several other jobs by a day or two—which means they’ll miss a deadline to be shipped to an external supplier for processing, and now your entire schedule is off by weeks.

If your business is still managing the production schedule on whiteboards or in Excel spreadsheets, it becomes nearly impossible to account for all those variables. Adding or moving jobs can’t be done without a heavy lift from your scheduler, and checking on a few different scheduling options is even less likely.

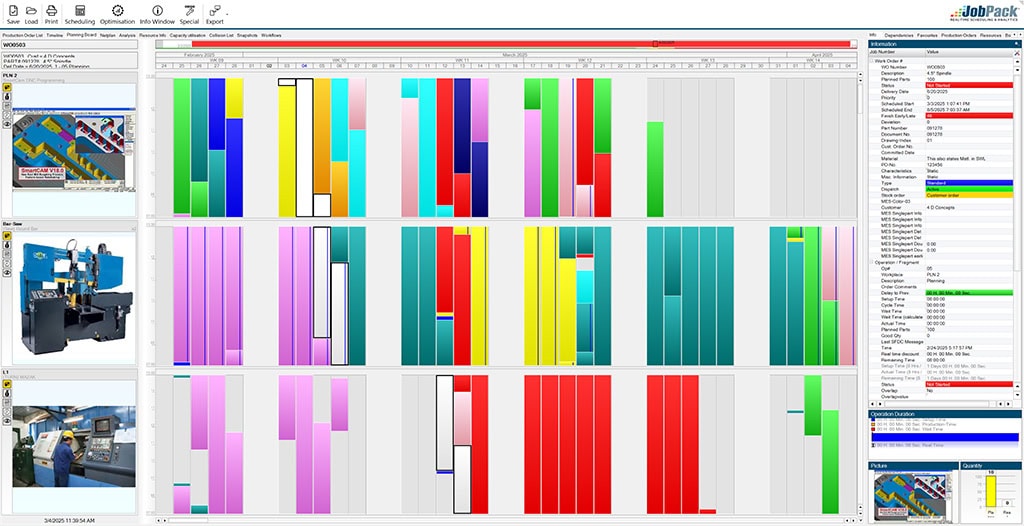

JobPack’s interface, by contrast, makes it easy to see the dependencies in your production process, and lets you try out alternate schedules by dragging and dropping jobs. Quickly assess whether you can move things around to accommodate a new job, or find gaps in the schedule where a low-volume run could fit.

Instead of a brittle schedule that doesn’t tolerate changes, JobPack enables you to adapt in real time and take advantage of surprise opportunities. With fast and intuitive planning, you’re free to ramp up the number of jobs you accept in line with your shop’s true capacity.

Impactful capital expenditures

Of course, capacity is finite, and even the most efficient production schedule will run up against practical limits eventually. When that happens, the next step might be an investment in additional staffing, an added shift, or a new piece of equipment. To maximize the benefits, though, you’ll want to invest in the piece of the puzzle that gives you the biggest bang for your buck.

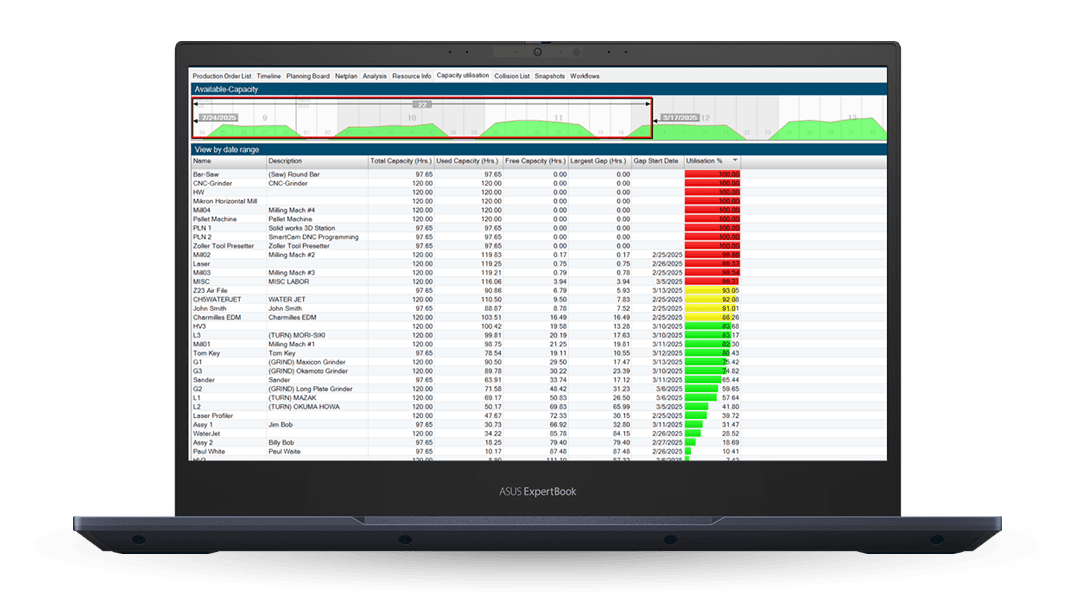

Finding the right change to make requires operational transparency. To identify your limiting factors and find any logjams, you need the ability to see your workflows clearly. JobPack gives you a detailed view into how your resources are being used, from equipment to labor to consumables.

With JobPack, you can identify where work stalls as you increase the load, and gauge where to scale up in order to keep it moving. Build a detailed business case for a new machine, more training, or a vendor switch in order to make the biggest impact on your available capacity. JobPack readily incorporates new resources into your workflows, and lets you customize their constraints to enable precise scheduling and reliable estimates—so you have the foundation to increase your capacity without adding to your logistical overhead.

New opportunities thanks to paperless production

JobPack is a strong first step in modernizing your manufacturing shop. Beyond providing a powerful, flexible production scheduler, JobPack also enables you to collect and utilize the shop floor data you already have, and connect it easily with other business information systems to find new kinds of efficiencies. And, crucially, it moves your production workflows off of paper job packs and into a trackable digital space.

Perhaps the first and most immediate impact of digital transformation is freeing up space in the shop. Paper packets are no longer lying around at risk of getting damaged, getting lost, or going stale. Your processes are more consistent, and all the relevant information is centrally located in JobPack’s database.

These capabilities make it much simpler to track and update jobs, view job histories, trace individual parts, and audit work. And when you can demonstrate this degree of consistency and transparency, new kinds of contracts become available to your shop: government or military jobs, for example, or healthcare products that require detailed traceability.

Digital transformation is the step that unlocks new spheres of business for your shop, and if you’re seeking to expand in those directions, a capable software platform for your operations is a must. But even if government or medical jobs aren’t in your plans, JobPack’s paperless production gives you the tools to optimize your shop in previously impossible ways.

Better predictions for more satisfied customers

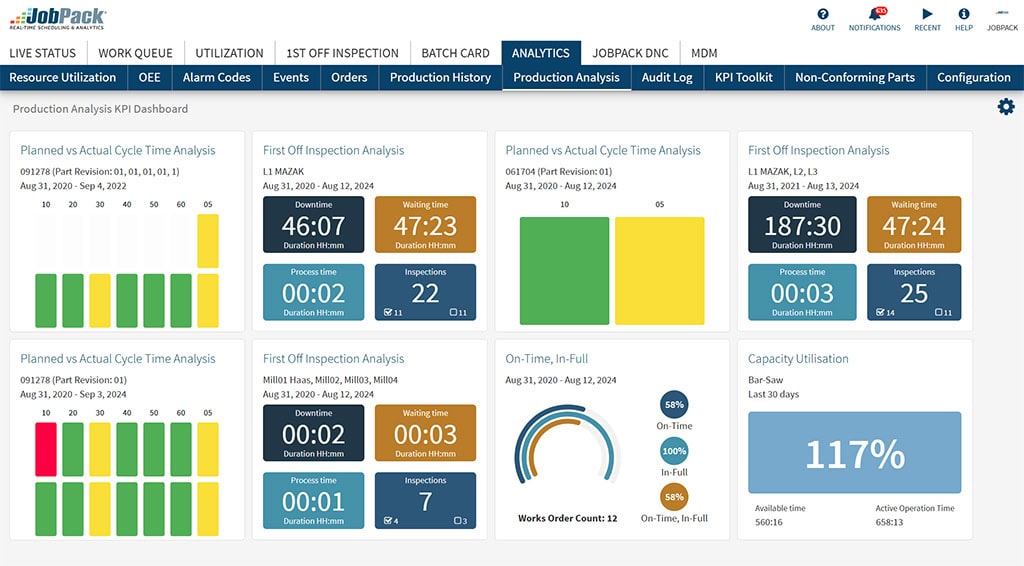

On top of being able to take on more work, JobPack’s transparency enables you to better estimate turnaround and delivery times. Standard manufacturing lead times don’t account for the unique variables of your production process and your business, and that means they can often let you down. But with JobPack, you can set accurate expectations with customers and reliably meet them, boosting your on-time delivery rate.

Easy access to production information lets you keep your customers informed, reducing frustration and helping you form stronger, more loyal relationships. Satisfied customers will spread the word about your business, support you with positive reviews, and even potentially make referrals, all of which broaden your reach and recognition, and pave the way for increased business.

The right tool can make all the difference.

JobPack is a lightweight production scheduler that installs quickly and starts delivering benefits fast. It’s designed with the needs of manufacturing shops in mind, offering a flexible solution that integrates smoothly with other manufacturing systems and targets the most stubborn challenges of a modern production shop.

If it sounds too simple to deliver on so much transformative potential, that’s because a lot of work goes into making it streamlined and intuitive. JobPack is designed to open the door to a new, data-driven way of running your shop, and to ease the transition into the next generation of manufacturing. Once you’re there, however, the sky’s the limit.

To see JobPack in action and learn more about how it can pave the way for your shop to scale up, contact us today for a demonstration.