On-Time Delivery Rate: Crunching the Numbers, and Why It Matters

Meeting your deadlines is a marker of both reliability and efficiency.

Every business relationship turns on one key variable: trust. Customers expect a certain level of product and service quality from suppliers, and when suppliers meet those expectations, the trust in the relationship grows. From a commerce standpoint, trust is a precious resource. It’s difficult to earn, easy to lose, and almost impossible to fake—but if you can establish it, you have the beginnings of a long and successful partnership.

On-time delivery rate (OTD) is a measure of how often you successfully deliver a job to your customers on or before the date you promised. OTD highlights your organization’s ability to meet its commitments—which makes it a quick and easy way to establish (or undermine) trust with potential customers. If you can showcase a high OTD, customers know you have a history of keeping your promises. They’re more likely to choose you for jobs, and more likely to be satisfied with the results.

In this way, investing in OTD can be incredibly valuable for manufacturers. But to raise your OTD, you need a thorough understanding of the factors that influence it, and the tools available to manage them. Join us for a deeper dive, and empower your manufacturing business to reach the next level of growth.

Calculating on-time delivery (and its benefits)

The formula for on-time delivery rate is fairly straightforward—although it can, like many metrics, become more complicated as you look at it in more detail. Put simply, OTD is the ratio of jobs delivered before or on their expected delivery date to all jobs delivered:

(Jobs delivered on time or early) / (Total jobs delivered) x 100 = OTD%

If your shop has delivered 50 jobs, with 48 of them on time or ahead of schedule, that would give you:

48/50 = 0.96 x 100 = 96% OTD

Standards vary by industry and shop size, but in most cases, an OTD of 96% would mean that you’re in good shape. If you’re new to monitoring OTD, 95% is often a good benchmark for excellence. As your shop grows, however, you might choose to aim higher—especially if you’re taking on jobs for customers in tightly regulated sectors, like healthcare or government contracts.

We’ve touched briefly on the benefits of high OTD for customer relationships. But the advantages of strong on-time delivery rates extend throughout your business, including:

- Improved customer satisfaction and loyalty: A satisfied client base reduces the costs associated with customer churn, promotes repeat business, and increases the likelihood that clients will recommend your manufacturing shop.

- Reduced logistical complexity: When jobs progress predictably, it’s easier to anticipate and plan around factors like procurement, storage utilization, shop capacity, and shipping.

- Fewer fees and penalties: Reduce costs by avoiding expedited shipping fees, late delivery penalties, and the financial and reputational setbacks that come from poor customer experiences. One study estimated that late shipments and penalties cost large companies, on average, $6.2 million per year.

Lack of transparency can damage OTD

No shop is perfect, and unexpected hurdles are always a possibility in manufacturing. But the more you can anticipate challenges and identify them early, the less they can impact your production processes—and, ultimately, your on-time delivery rate. That’s why shop floor transparency is a key factor in raising and maintaining your OTD.

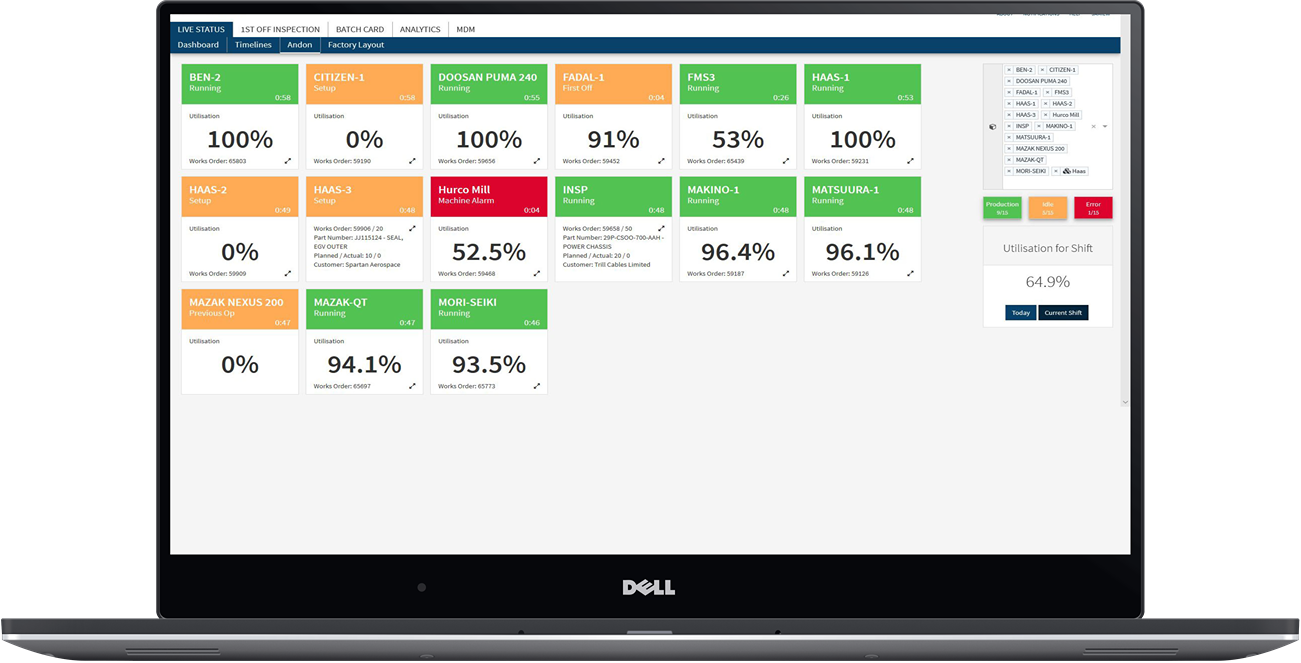

High visibility into your operations enables detailed monitoring, which lets you spot hurdles before they can cause too much damage. Keep a close eye on your inventory, for example, and catch supply shortages as they occur (and not when you’re in the middle of a critical process). Machine monitoring capabilities also allow you to track equipment performance, so you know immediately when an essential machine goes down. In many cases, you can see degraded performance before a machine fails, and schedule preventive maintenance instead of facing unexpected downtime.

Technology enables shops to respond to disruption flexibly

Anticipating setbacks is only half of the equation, however. Shops need the ability to respond in real time to changing circumstances in order to forestall the hardest hits to OTD rates. But if your shop is still managing schedules in spreadsheets or on whiteboards, a quick pivot can be almost impossible.

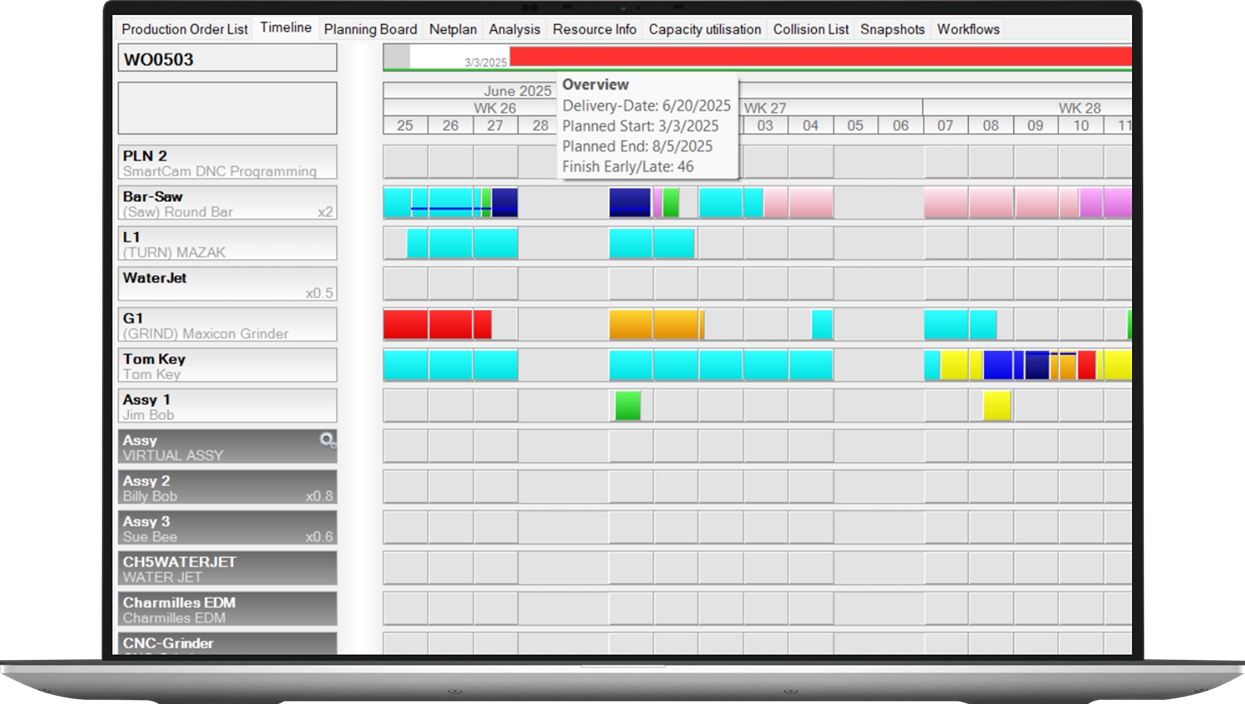

A flexible, capable production scheduling platform is a key ingredient in developing a more agile production process. Scheduling software can automatically generate the most efficient production plan based on your shop’s unique resources and priorities, and will run out the downstream implications of any tweak you make to those variables. With this kind of visibility, you can quickly optimize your planning and communicate accurate expectations to clients—or, if circumstances change, you can evaluate your options and redirect your efforts immediately.

Customers value knowing what to expect, sometimes even more than they value speed. Robust production planning software helps you harness your shop data to create the most accurate estimates possible, and hands you the granular control you need to reliably meet expectations.

Reinvent your standards for on-time delivery with JobPack.

The more you increase your visibility and control over your shop floor, the more you can improve your on-time delivery rates. JobPack is the lightweight-yet-powerful production scheduler that unlocks your shop’s fullest potential.

Endlessly customizable and simple to integrate with your existing software stack, JobPack captures the data that already exists in your shop and puts it to work for you. Take advantage of its analytical tools to optimize your shop’s efficiency, maximize the accuracy of your predictions and estimates for clear communication, and leverage “what-if” scheduling to adapt on the fly. With JobPack, you can raise your on-time delivery rates by 15% or more.

Learn more about how JobPack helps you drive excellence with your existing shop data and request a demonstration today.