Faced with the unexpected, the right tools let you pivot and adapt.

Even though supply chains are starting to find a new equilibrium after the confusion of the pandemic, disruptions remain the rule rather than the exception. Nine out of ten respondents in McKinsey’s Global Supply Chain Leader Survey said they encountered supply chain challenges in 2024. Extreme weather events, materials shortages, geopolitical events, and fluctuating tariffs all continue to cause instability in supply chains, and few industries feel the impact more than manufacturing.

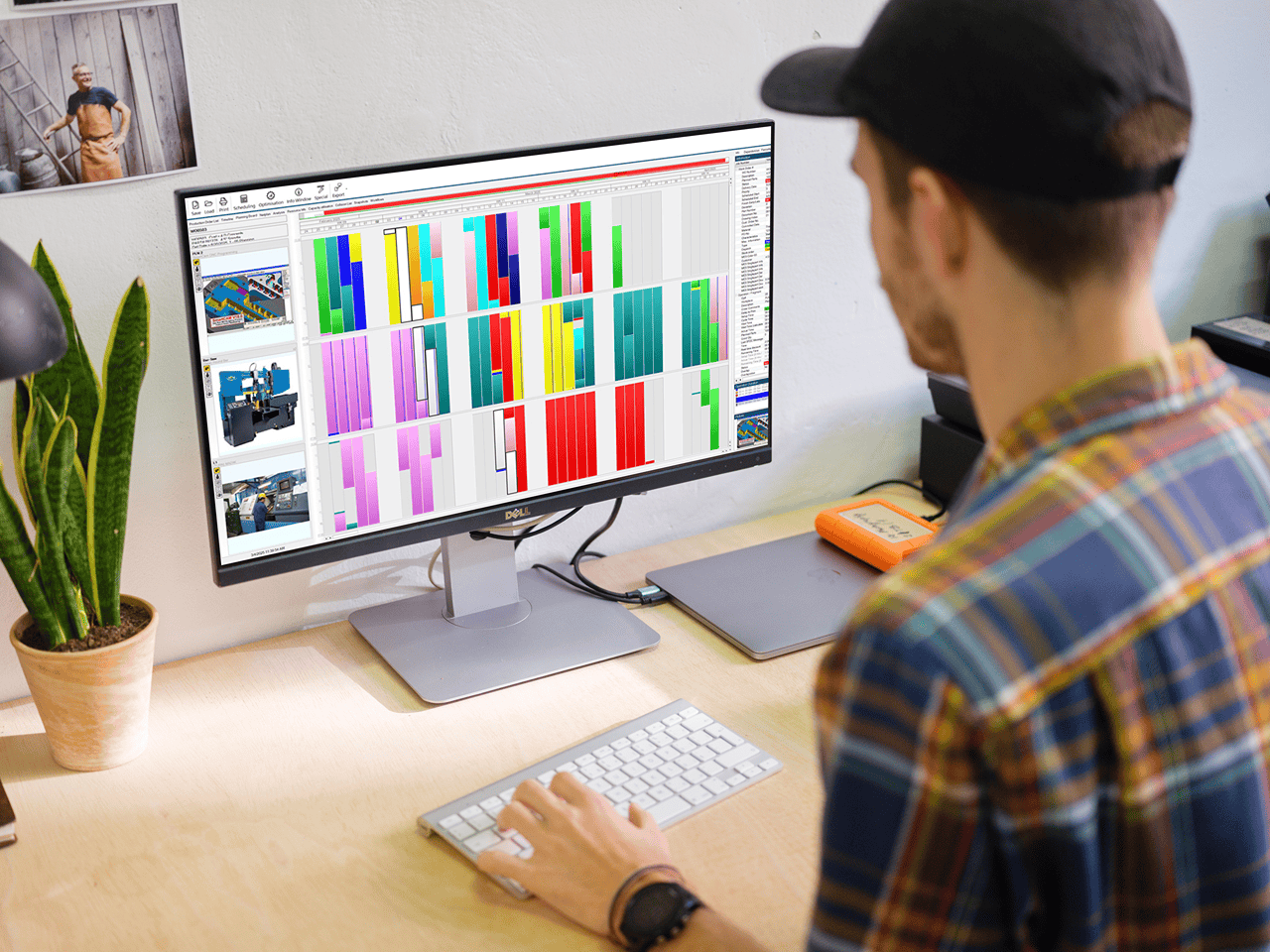

Unexpected supply challenges can throw a wrench into everything from labor cost to customer relationships. In uncertain times, manufacturers need a way to heighten visibility across their supply chains, pivot quickly when changes happen, and forecast reliably to make informed decisions. With a flexible production scheduler like JobPack, manufacturers can unearth the insights that help them weather supply chain disturbances. Here’s how.

1. Track supplier details and their impact on scheduling.

Suppliers each have their unique constraints, even under ideal circumstances: one may not deliver on certain days of the week, or another might have limited holiday hours. With JobPack, you can enter each supplier as a resource, and specify any additional considerations—which JobPack will then factor into scheduling for you.

As circumstances change and suppliers face their own hurdles, their constraints might change. If raw materials are scarce, they may reduce shipments, or excess costs could reduce their hours. Keep their details up to date in JobPack, and these changes won’t slip through the cracks to trip you up.

2. Monitor inventory and set custom alerts.

Inventory management is a core tool for adapting to supply chain disruptions. Manufacturers might frontload their supply to circumvent rising costs or prepare for scarcity down the line. If lead times are longer, you might choose to reorder consumables when you have 35% of your stock remaining, instead of 20%.

Monitor inventory in detail with JobPack and create custom alerts to prompt you to reorder at the right time. As lead times and availability shift, you can move your alerts to account for delays and keep your warehouse stocked with essentials. Automation allows a little bit of proactive management to go a long way, ensuring that even minor scheduling tweaks are uniformly applied.

3. Flex your schedule when disruptions arise.

Even in the most proactive and prepared shops, it’s impossible to account for every detail. Eventually, disruptions will happen. A shipment of essential supplies will be delayed or canceled, or materials will suddenly be impossible to source, and a job will have to be rescheduled.

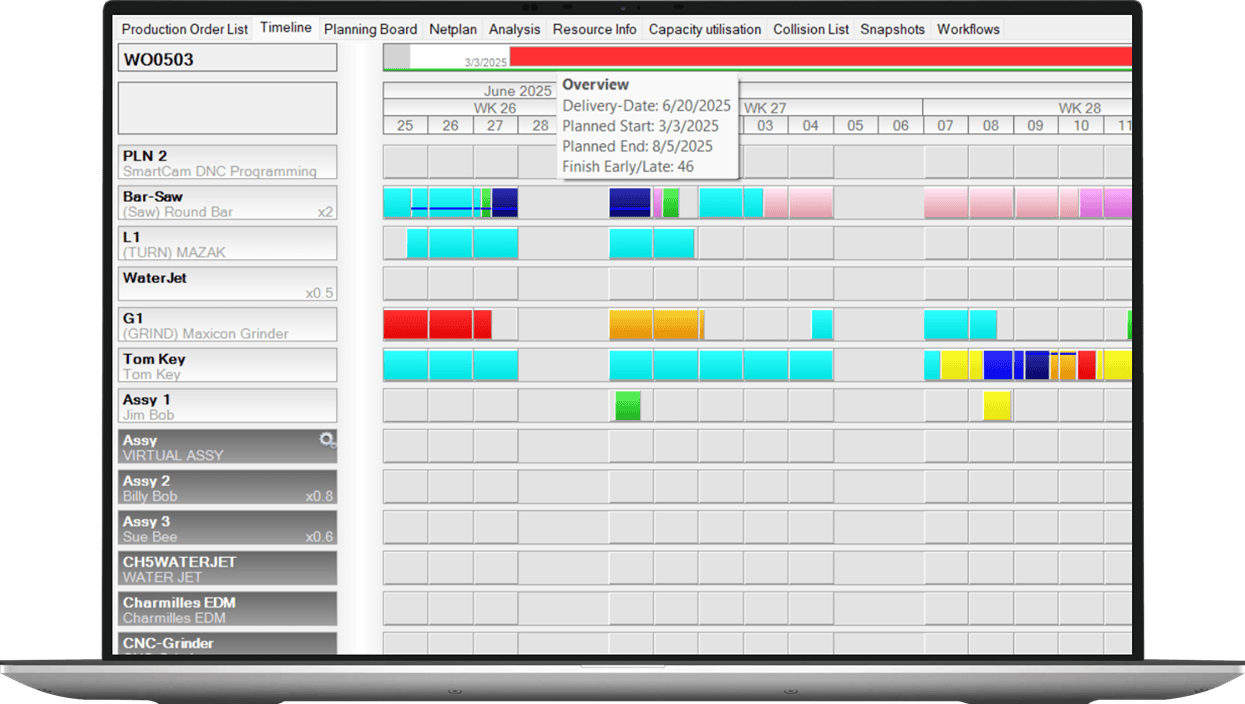

If your shop is still managing schedules on whiteboards or in spreadsheets, rearranging could be labor-intensive and lengthy. JobPack allows for “what-if” scheduling, letting you drag and drop jobs and automatically running out the downstream impacts. Implement the new schedule, revert it with no permanent changes, or save it as a snapshot and continue analyzing your options. With JobPack’s flexible scheduling, you can adapt to whatever the supply chain throws at you.

4. Trace materials in detail for quality assurance.

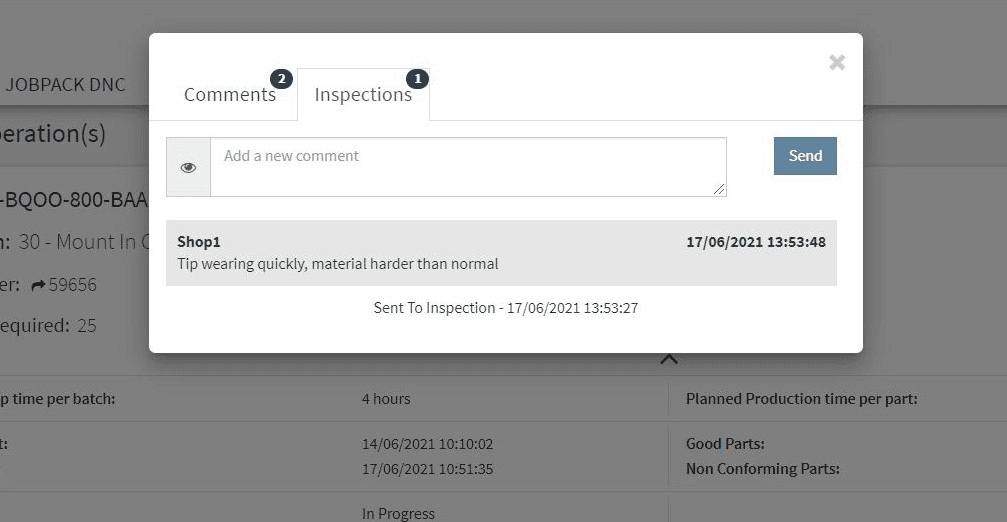

Disruptions in your existing supply chain could spur you to connect with new vendors. While diversifying your supply chain is generally helpful, incorporating parts or materials from a new supplier always carries some amount of risk, however small. The supplies may carry flaws or be incompatible with your other inventory.

In the unlikely event that your shop turns out a flawed lot of product, JobPack provides the tools to trace the root cause. Track parts and materials throughout your production process using unique identifiers, and you’ll be able to uncover any links between new supplies and product quality. Traceability helps you maintain your quality standards and gives you more certainty as you work to diversify your supplier options.

5. Communicate dates and expectations confidently with clients.

As circumstances and production schedules change, so too will your expected delivery dates. Transparency is fundamental to maintaining good relationships with clients, and so is fulfilling your commitments dependably. If the timeline of a client’s project changes, you’ll naturally want to let them know—and give them an accurate idea of when they can expect it.

JobPack’s flexible scheduling capabilities let you adjust your production plan quickly, and factor in your shop’s unique variables for the most accurate timelines possible. With all the information at your fingertips, you can update your clients as soon as changes happen, and keep your most important relationships strong.

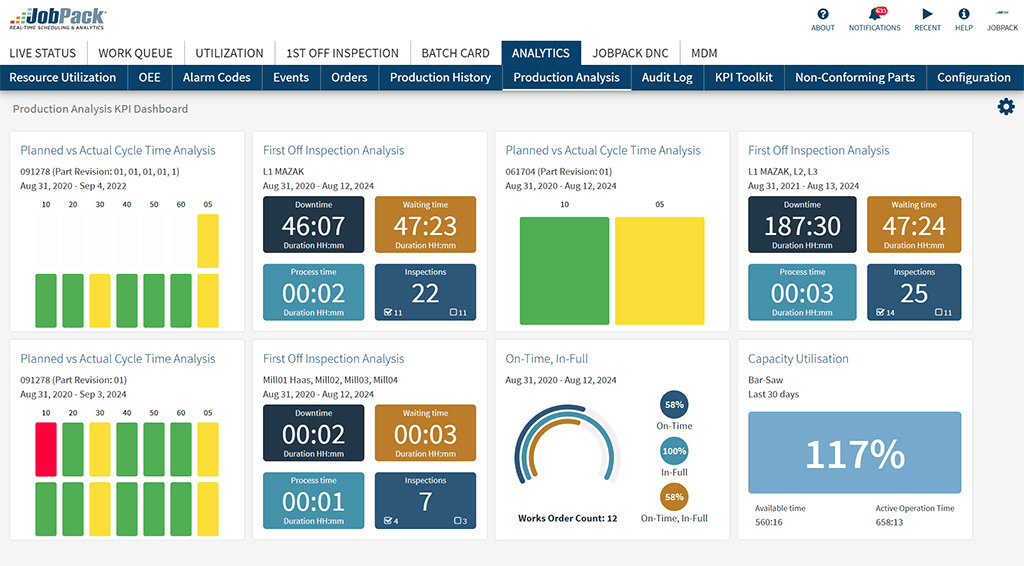

6. Collect the data you need to make informed supply chain changes.

Responding to emergencies in the short term is part of any business, but if disruptions continue for long enough, you may want to consider a bigger change to your supplier strategy. As tariffs continue to evolve, for example, sourcing materials domestically might become a higher priority. There are a lot of factors to consider, though: labor costs, variations in materials, shipping logistics… the list goes on.

With so many moving parts, making the best business decision would be an overwhelming prospect—but data can make it easier. JobPack collects the information that already exists in your shop and puts it to work for you, shining a light on your current costs in detail and giving you the analytical tools to weigh your options. Use your shop’s historical data to shape your future supplier strategy and find the best way forward as the market changes.

Turn uncertainty into answers with JobPack.

Today’s manufacturing landscape is evolving rapidly, and supply chain disruptions are all but inevitable. To navigate the chaos, manufacturers need as much information as they can get. The best place to start is unlocking the insights that already exist in your shop’s data.

JobPack is the lightweight, intuitive production scheduler that can help you gain a new level of visibility into your supply chain, and empowers you to act on your new insights. To learn more about how JobPack can keep your shop on top of unsettled supply chains, request a demonstration today.