JobPack® has been specializing in digital solutions since 1992, so we understand the importance of connecting the right data with the right people to make informed decisions.

Owners & CEOs gain deeper operational insights.

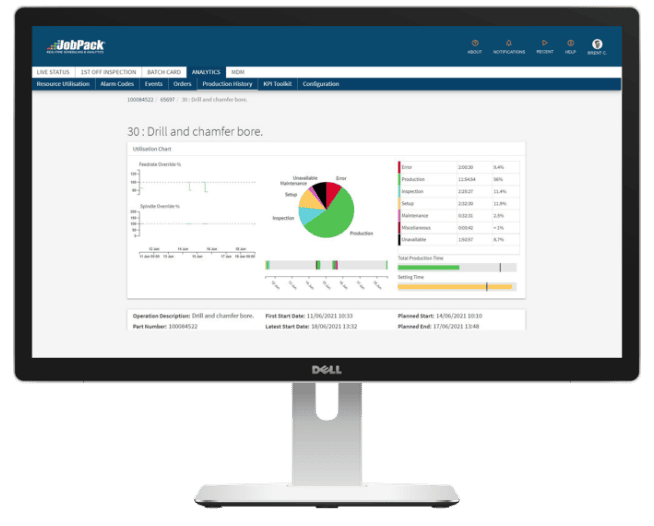

To make effective decisions about manufacturing execution, you need the right data at the right time.

The spreadsheets and ledgers you have come to rely on can only take you so far. You might not even have exposure to the information that is the most important. Are jobs taking longer than they should? Where might you be losing money? Now you can know.

- Make better decisions with enhanced pricing guidance and sales staff management data

- Maintain just-in-time raw material inventory levels with advanced scheduling

- Enhance month-end budgeting with a better visualization of projected vs. actual costs

- Improve on-time delivery rates by identifying and eliminating unknown bottlenecks

- Reduced overtime expenses with improved forecasting data

- Gain visibility into customer commitments and production capacity

- Draw upon machine utilization data for capital expense planning