Don’t miss the essential tools already in your toolbox.

If you know JobPack primarily as a production scheduler, you’re already aware of the detail and flexibility it offers. But any shop manager knows that there can be a world of difference between the plan you lay out and what actually happens on the production floor. And when the plans don’t match the actuals, it’s more often than not the schedulers who end up fielding the questions.

Manufacturing is already a data-driven industry, and as capabilities evolve, the reliance on data only grows. JobPack is designed for the demands of a shop floor, and that includes the push for more real-world data to shape decision-making. Our machine monitoring module was built to address that push.

Schedulers are tasked not only with building the most efficient production plan, but with continually finding efficiency gains, and responding in the moment to disruptions. Machine monitoring offers you real-time visibility into what’s happening on the shop floor, providing the insights that let you realign your approach from a reactive one to a proactive one. Below are five things schedulers can do with JobPack’s machine monitoring capabilities to take production planning at your shop to the next level.

1. Turn data into optimization

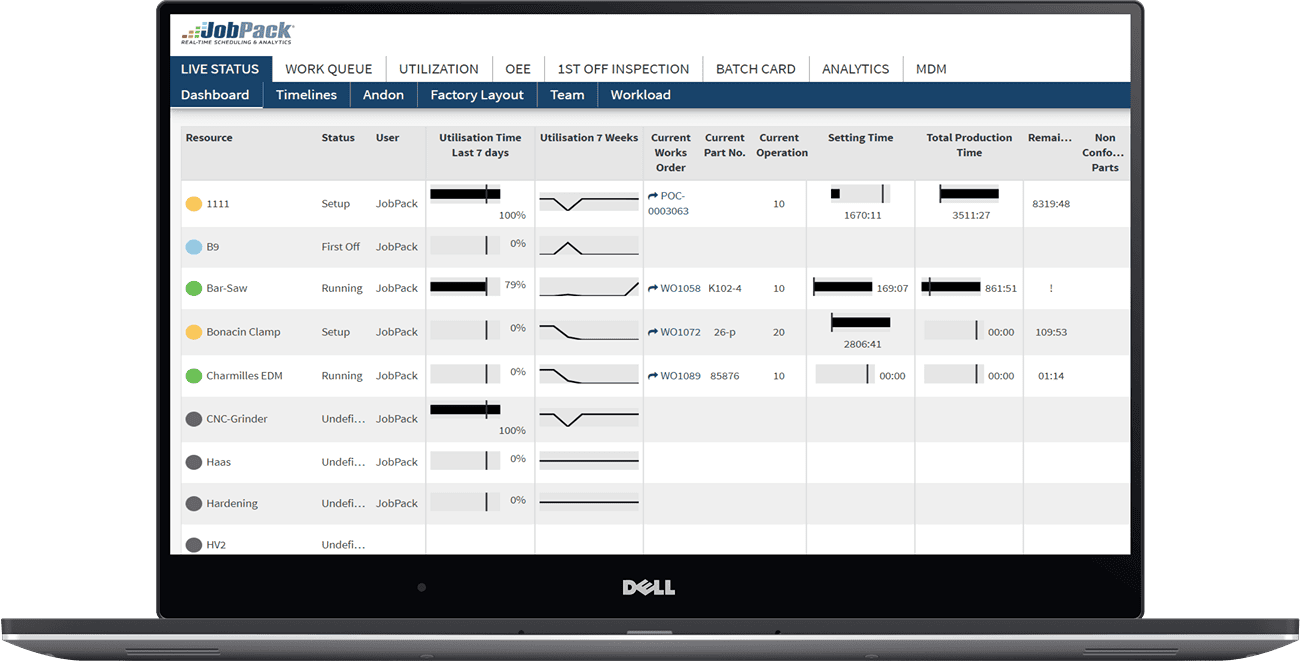

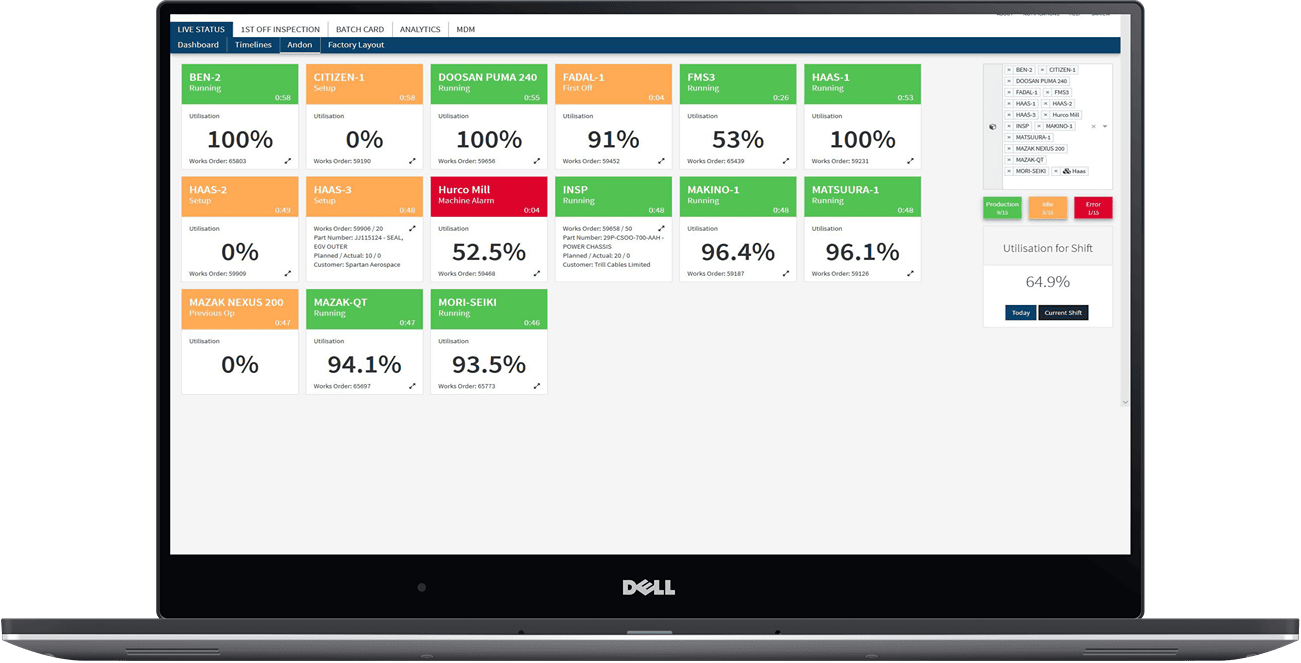

JobPack automates gathering data from virtually any machine on your shop floor, even legacy equipment. Operations, status changes, conditions, timestamps, and cause codes can be viewed in straightforward visual dashboards, or exported for deeper analysis. JobPack can also share data with your ERP, letting you incorporate data from other departments into your analyses.

This in-depth machine data adds context to your planned vs. actual results. You can isolate the step of a process that’s causing delays, or spot differences in shift performance. With that detail, you have the tools to keep adjusting your production process closer and closer to maximum efficiency.

2. Support scheduling decisions with cold, hard facts

Every role in a shop faces its own pressures and priorities. Owners, sales teams, and account managers answer to customers, and when customers need something, they’re the ones who feel the pressure. That pressure can show up in the form of schedule change requests, to turn around a job faster or work a “small” job in at the last minute.

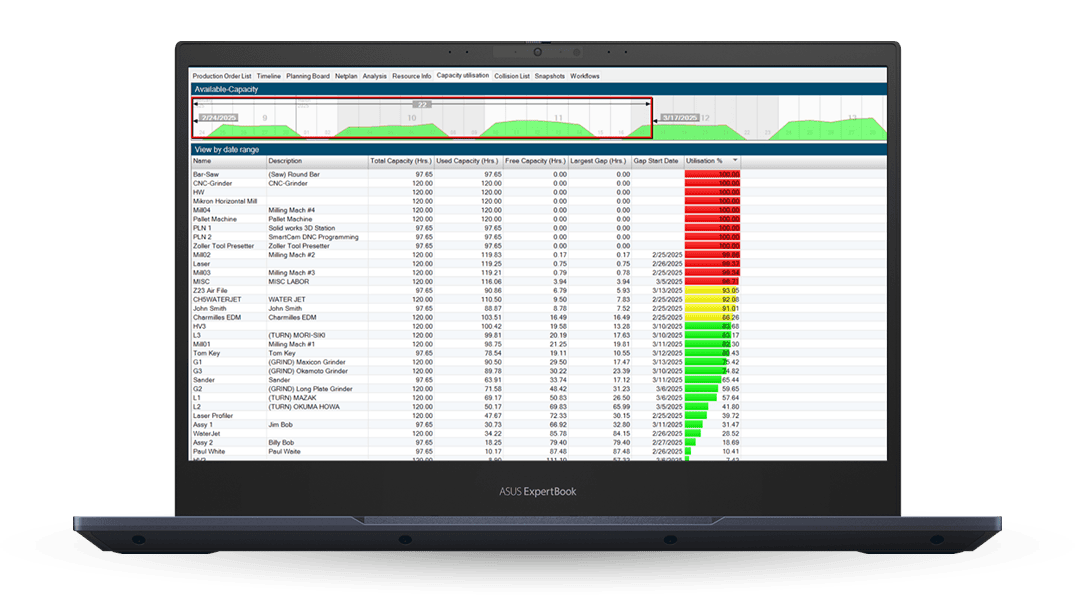

Powerful scheduling tools like JobPack make it a lot easier to absorb these changes and even profit from them—but at the end of the day, a shop’s capacity isn’t unlimited. As a scheduler, there are times when you have to draw the line. Maybe you technically have time to run an additional cycle on one machine, but you know that resetting the machine afterward will take extra time, causing cascading delays in your schedule.

With machine monitoring, you can show your work, highlighting exactly where the problems will occur, and the effects they’ll have downstream. Your team will know you’ve got the data on your side, and you’ll have breathing room to keep your plan on track and reliable.

3. Catch setbacks as they develop

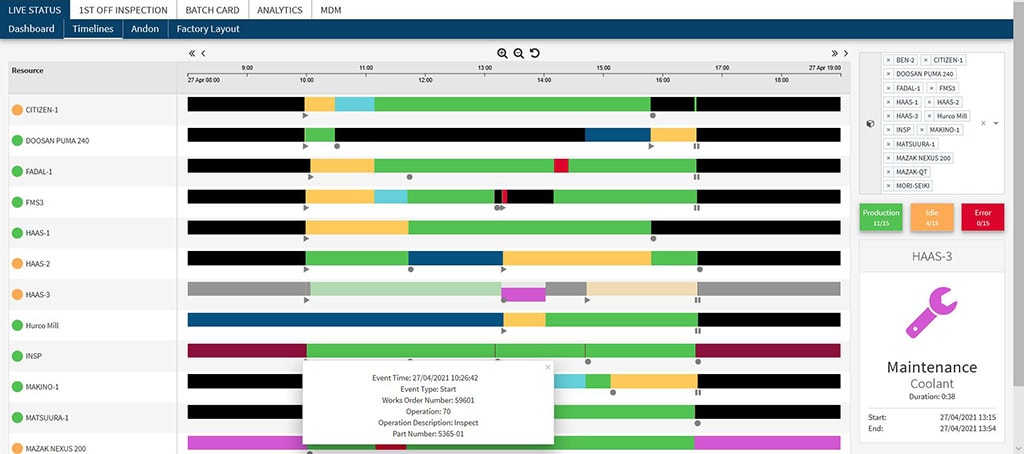

Uncovering the difference between planned and actual productivity is much easier when you can watch production unfold in real time. When all you have is the results, you’re limited to trial and error—change one variable, and wait for the next run to see if it worked. If you can see your machines running in real time, you can spot slowdowns and bottlenecks as they happen. With JobPack, you can even set customizable alerts, so you know right away if a machine goes down or falls outside of parameters.

With this kind of real-time information, you’re equipped to respond dynamically to whatever the shop throws at you. Machine operating more slowly than usual? Reassign work to another one while you investigate the issue. Need materials? Resupply just in time so work can keep flowing. JobPack’s detailed monitoring helps you respond immediately to, or in some cases even preempt, the real-world hurdles that can sidetrack your plan.

4. Schedule maintenance before your machines schedule it for you

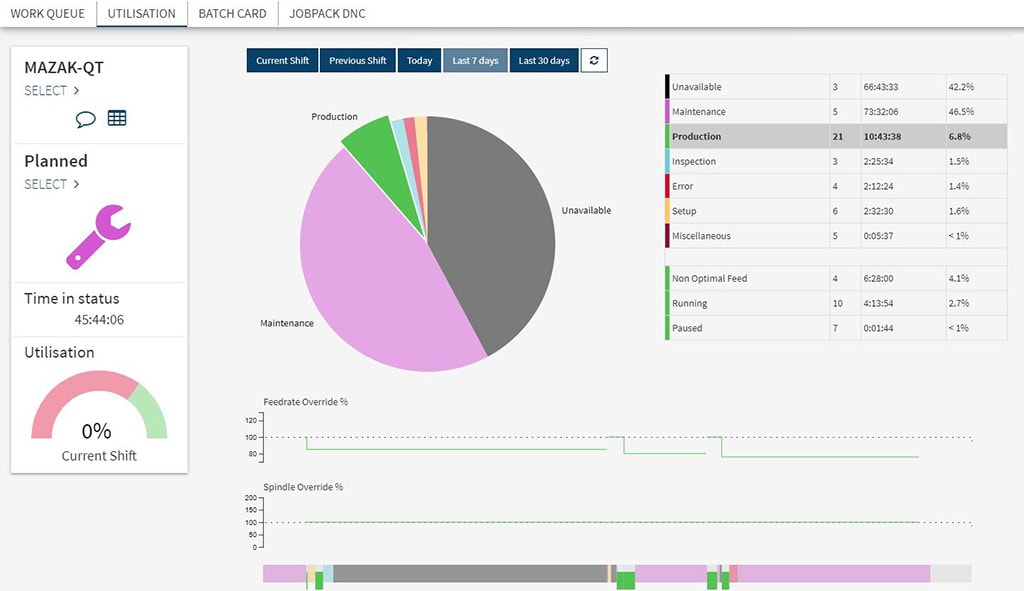

Unplanned downtime is expensive. Not only do you lose productive hours on the affected machine, but you could also lose materials, delay other jobs, or—depending on how catastrophic the equipment failure is—even have to replace the machine entirely.

Machine monitoring gives you a close look at equipment performance, so you can see exactly when a machine starts to struggle or wear down. Once you spot the signs, you have the opportunity to schedule maintenance or repair at a time when it will have the lowest impact on your production plan. Over time, collected machine data can also reveal patterns in equipment wear, so you can even plan production around the inevitable maintenance windows—which means zero penalty to your output or on-time delivery rates.

5. Update your teams in real time

We’ve seen how machine monitoring connects schedulers to a tremendous amount of helpful information, which you can use to optimize your production process down to the finer details. But schedulers aren’t the only role that benefit from access to machine data—and fortunately, JobPack makes it easy to share.

JobPack empowers you to build machine status dashboards that show key performance indicators clearly at a glance. By displaying live data on the shop floor, operators and other stakeholders can see how the shop is running and align their work accordingly. See instantly when a machine throws an alarm, and identify the best resource available to check on it. In addition, as you update your schedule to account for roadblocks and changing needs, JobPack acts as your single source of truth, immediately and consistently providing the most current information to everyone in the shop.

Machine monitoring is the bridge between your schedule and the shop floor.